Industry High Precision

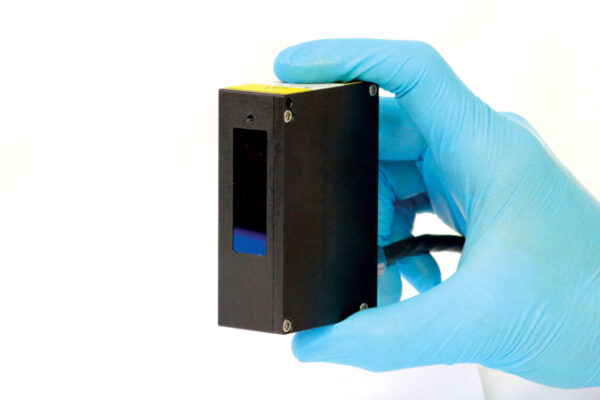

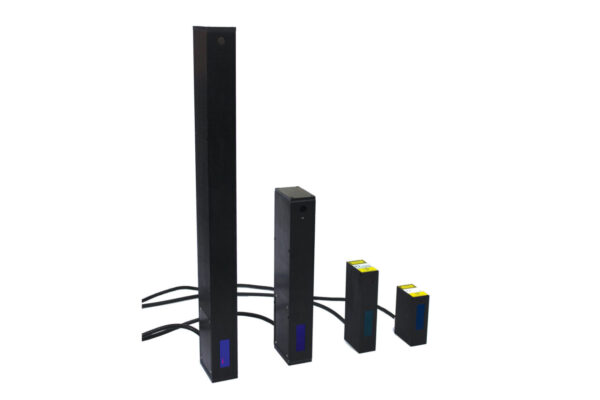

The AR700 laser displacement sensor series includes fourteen models with measurement ranges varying from 0.125 inches (3.2 mm) to 50 inches (1270 mm). The AR700 linearity is among the best in the industry at ± 0.03% of the measurement range. All models in this series have a 0.005% resolution throughout the measurement range and some models can even achieve resolutions down to one sixth of a micron. Acuity takes pride in the fact that our specifications are true in real world situations. We encourage customers to ask for previous AR700 calibration certificates to serve as examples of the sensor’s true precision under ideal conditions.

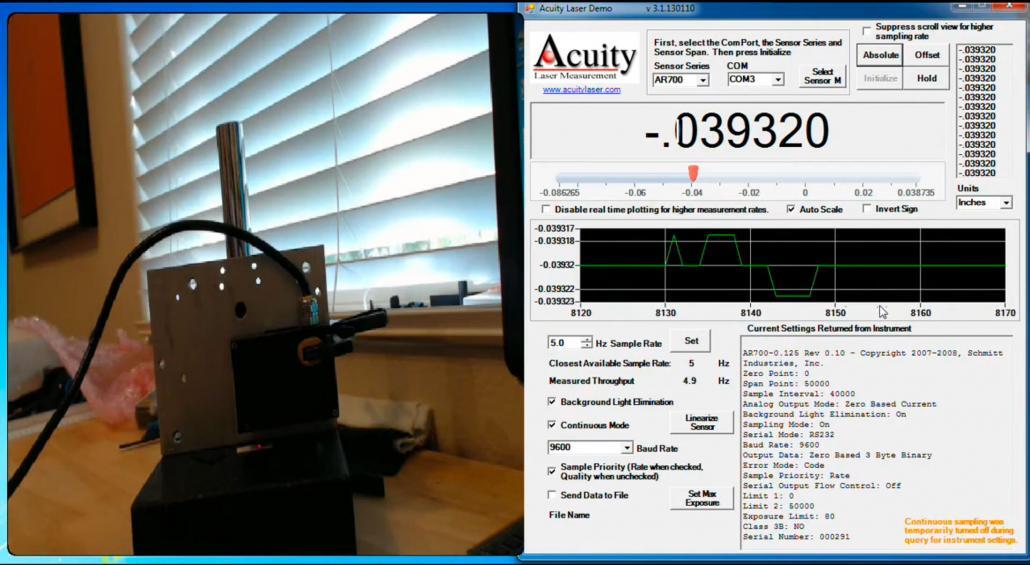

High Speed Capability

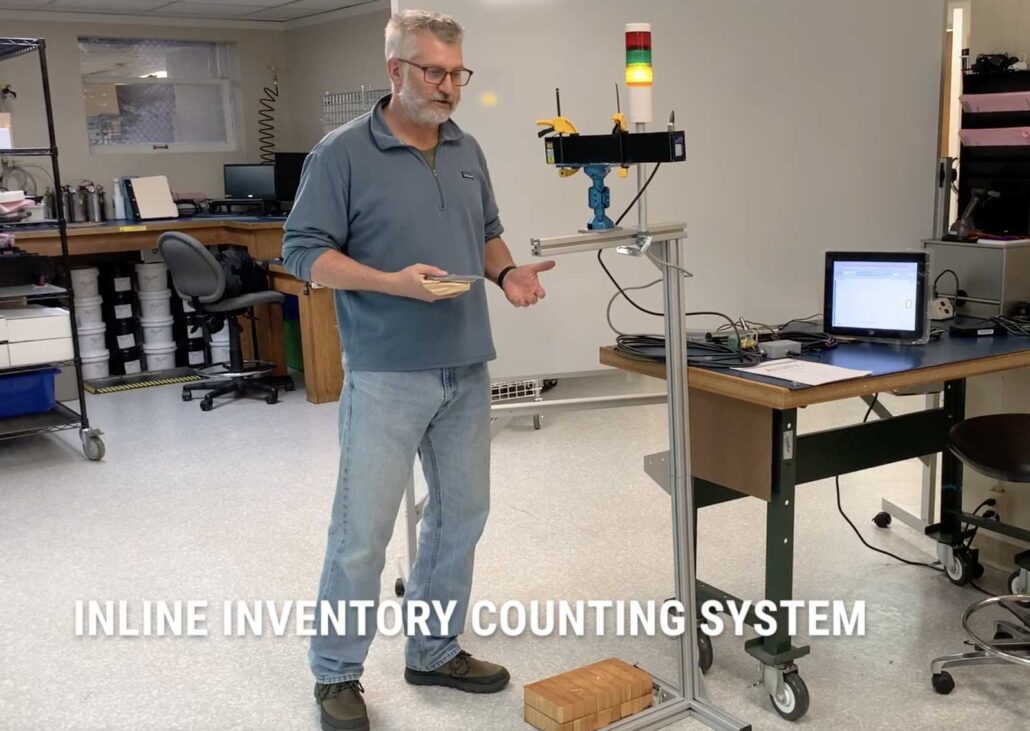

The AR700 sensor offers adjustable sampling rates of up to 9400 Hz to satisfy high speed applications. A special trigger mode can be used with the AR700 for synchronization of multiple sensors, but in that case, the maximum speed is reduced to 4500 Hz.

Input/ Output Options

The AR700 laser displacement sensor is standard with a variety of serial and analog outputs. For serial communication, RS232 and RS422 are both included for communication with a computer or PLC. RS232 and RS422 data formats include ASCII English, metric, native and two binary outputs. The sensor can output error codes for: Target too near, Target too far, Target not seen and Laser off.

Analog outputs include a 4-20 mA current loop, 0-10V outputs and two NPN sinking limit switches. All parameters and settings are selectable either from push-buttons on the sensor or through PC serial commands for ease of use.

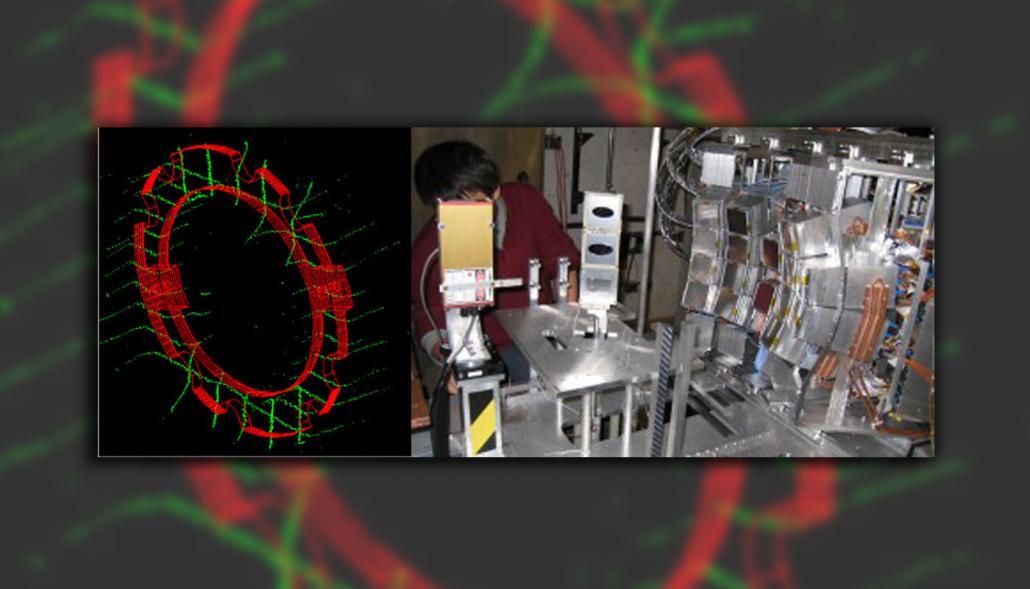

Built for Applications Needing Top Precision

The AR700 displacement sensor laser offers different sensor options to satisfy a wide variety of environments and applications. Different laser powers and optional bandpass filters can be ordered for improving sensor performance in applications with high ambient light or in measuring distances to targets that are radiating, dark or shiny. All AR700 laser sensors come with programmable options for background light elimination, sample priority, and exposure limit controls to improve the sensor’s performance in certain environments.

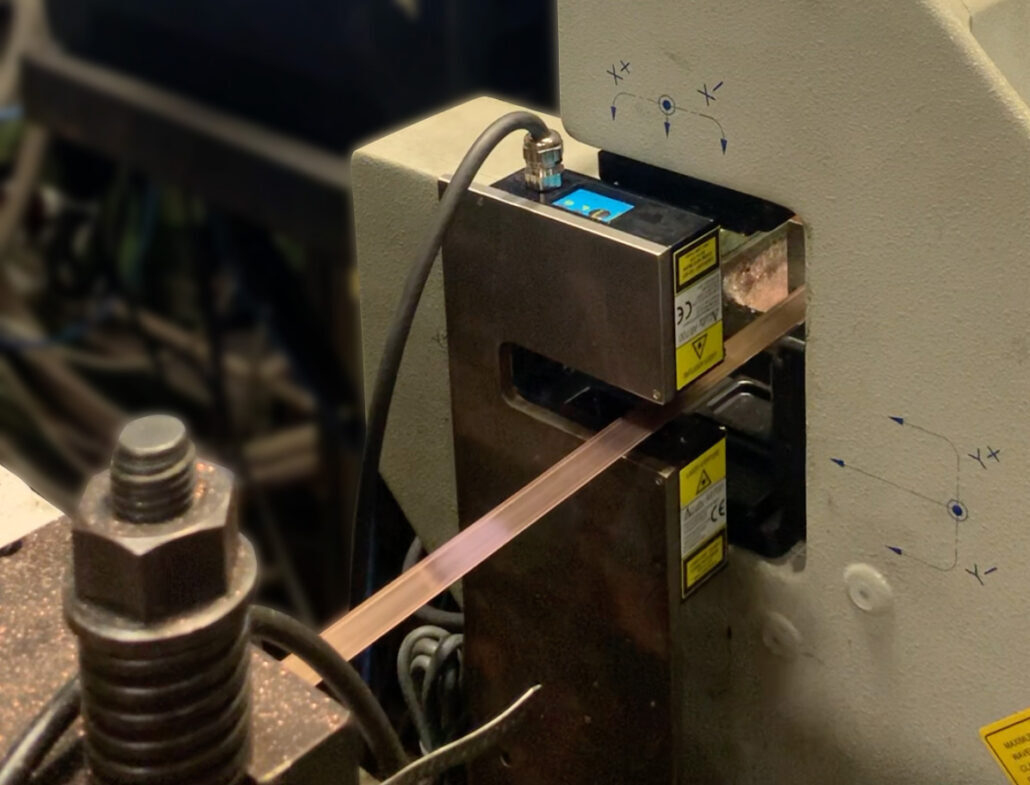

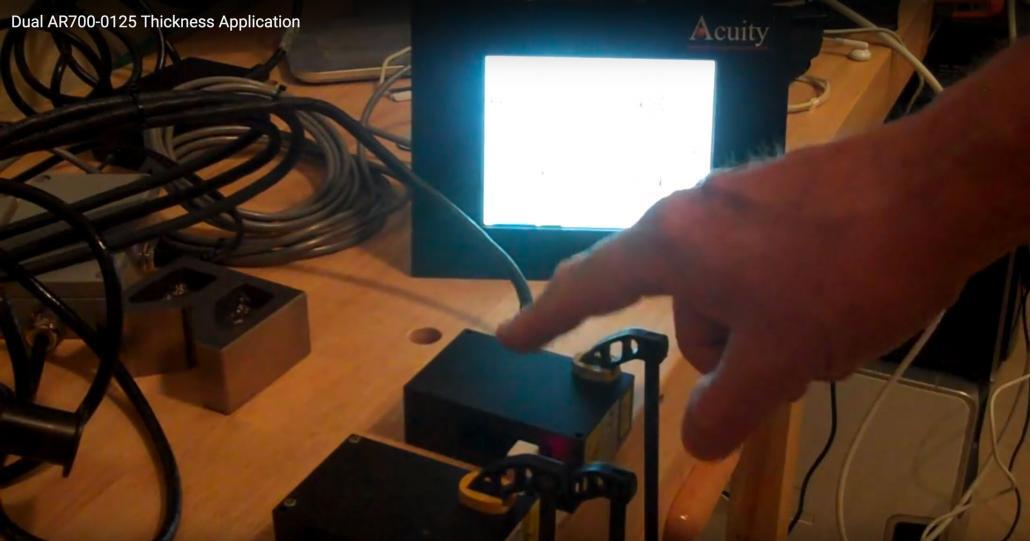

All models in this series have a built-in automatic gain control feature to ensure quality measurement despite variations in target colors. The AR700 is commonly used in traditional applications such as thickness, position, and distance measurement, but is most requested in applications that require the upmost accuracy and precision.