Battery Expansion Laser Displacement Test Posted in: Displacement Measurement – Tags: AR700, Customization

A US manufacturer was looking to find a system to precisely measure the displacement of a battery cell during a battery expansion measurement test. This customer was looking to measure the battery cell expansion under cycling and other pressures in a controlled temperature environment in order to use the results and method to guide the battery cells design. The manufacturer was looking to use non-contact measurement to precisely monitor the displacement without the drawbacks of touching the material. They were looking to collect multiple data points across the target material to see the rising and lowering of the expansion to determine the evolution of the entire cell.

Using non-contact laser sensors, the customer was looking to analyze the location(s) of the battery expansion to see if it is uniform or not; all while maintaining accuracy down to a micron. The laser displacement sensors station was for battery R&D testing, and the customer requested an out-of-the-box solution without the need for software programming on their end.

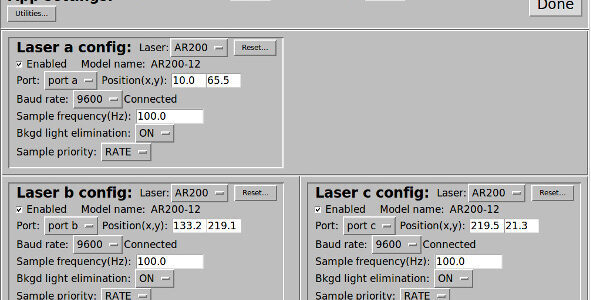

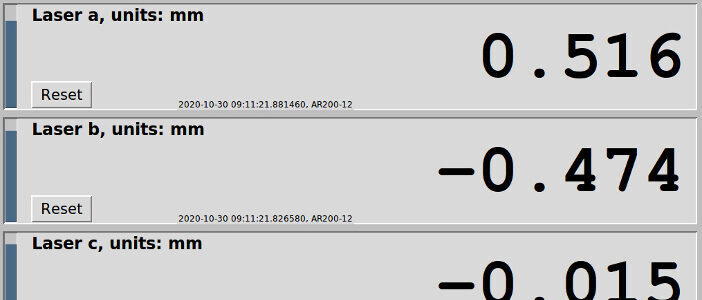

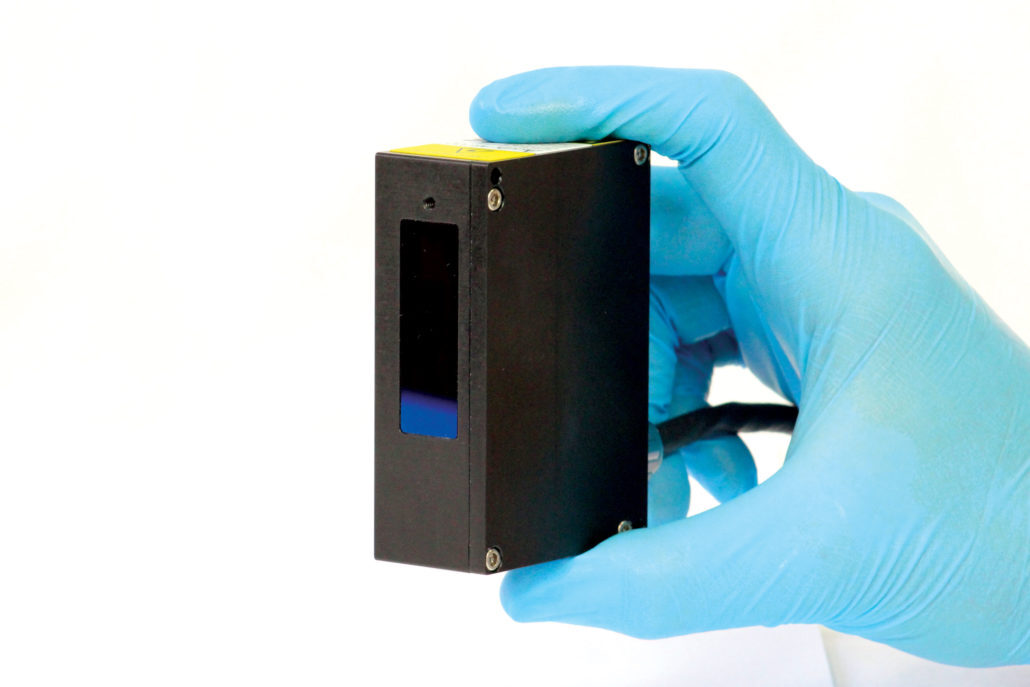

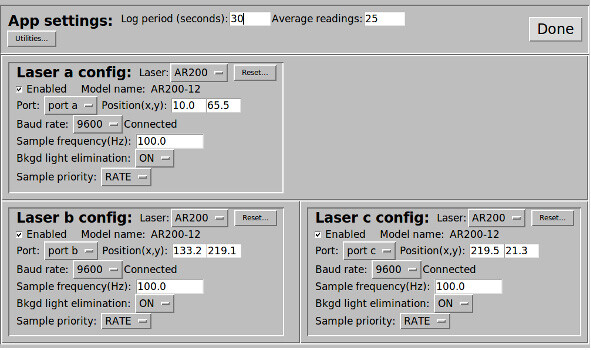

Through a few discussions, Acuity engineers were able to design a laser measurement system to provide the customer a small customized solution. Acuity engineers selected (3) AR700-0125 laser models and a touch panel display with customized software. The AR700-0125 laser displacement sensor was selected due to its industry leading accuracy & resolution for triangulation sensors. With 0.125 inches of measurement range, linearity down to less than a micron, and resolution down to 0.16 microns, the AR700 was the right laser sensor for the job.

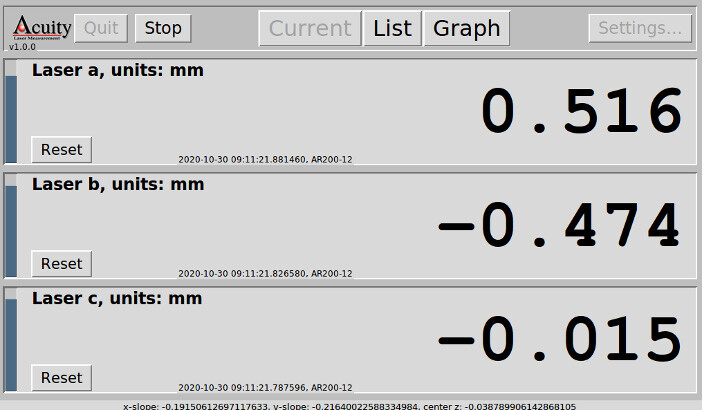

Custom software was written in order to calculate and record the individual displacement of the three lasers, as well as to calculate and record the x-slope, y-slope and center-z of the target surface. The software allowed the customer to go into the settings and copy the data via a USB thumb-drive to receive logged measurement data up to total capacity of 300MB. The customer was then able to download the data into an excel spreadsheet file to further analyze the three laser displacement measurements over time and analyze the x, y, z angles to graph a visual virtual plane.

Acuity’s touch panel display allows the flexibility to develop small solutions without the need for your team to spend the extra time and money developing your own software program. Acuity offers other customized software options to provide small system solutions. If you want to explore customized software or hardware for your non-contact measurement application, please contact Acuity.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.