Copper Bar Cut-to-Length Posted in: Length Measurement, Updates – Tags: AS2100, Metal and Steel Production

Acuity helps identify both non-contact solution and upgrade investment justification for copper bar manufacturer

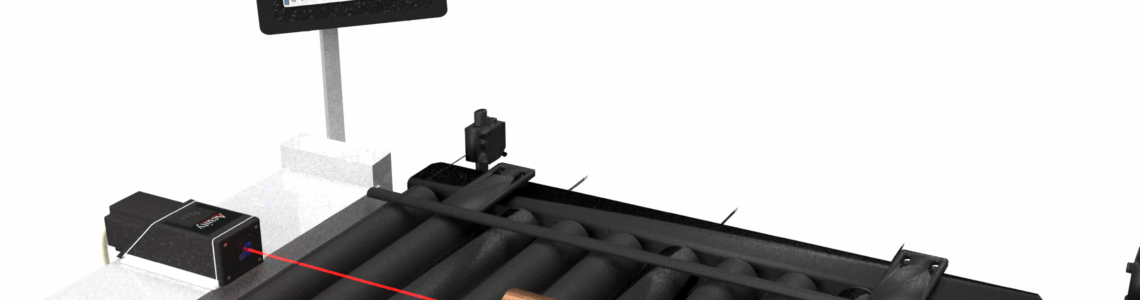

Acuity recently helped another customer out with a cut-to-length application. This customer was looking to upgrade their current cut-to-length measurement process. The customer’s current process was using a tape measure to measure lengths of the copper bar before using a shear to cut the copper bar to specific lengths. During more discussions with the customer, the Acuity team learned about the application. The copper bar lengths ranged from 300 to 4000 mm and the accuracy expectation was +/- 1.5mm. In addition, the customer was wanting a software solution to display the actual cut length at the workstation.

The Acuity Team has helped a lot of customers through this exact type of application. Given the measurement range and accuracy needed, this was a perfect application for the AS2100 laser distance sensor and the Acuity touch panel display. However, sometimes during the course of product discovery, even if a laser solution works, measurement upgrades and technical investments need to be justified to upper management. This was the exact case for this application. After further discussion, the Acuity Team was able to identify (3) main high-level benefits to sell this cut-to-length laser sensor solution to upper management. Amongst others, the (3) biggest benefits from this solution are:

- Upgrades in Safety – With this solution, there is no need for people to be around material that is being cut-to-length. Industrial environments, where metal is being cut can dangerous, especially with employees trying to take manual measurements of material while being cut-to-length.

- Increased Reliability – laser sensors provide fast, repeatable, accurate non-contact measurement. When compared to manual measurement such as tape measures, laser sensors outperform in reliability & speed, making the solution an easy upgrade.

- Reduction in Cost – Using laser for this application is actually a cost reduction due to elimination of cut errors. A miscut due to measurement issues can cost the manufacturer a ton of money and time. Laser measurements are very accurate and are a fraction of the cost that miscuts result in.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.