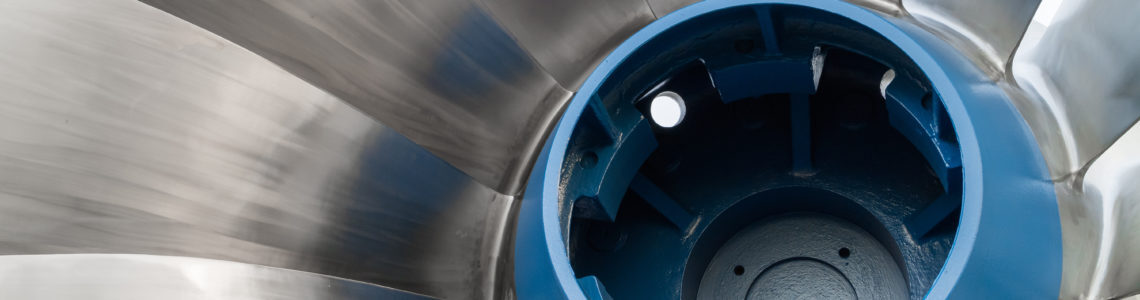

Hydro Turbine Alignment June 8, 2020 – Posted in: Displacement Measurement

Hydroelectric engineers in Wenatchee, WA needed a precise, non-contact method for aligning the turbine blades in the system’s housing. They selected an AR700 laser displacement sensor to measure the distance from a known location on the turbine to the sidewall.

Continue reading