Drill Pipe Runout Posted in: Runout-Vibration – Tags: Mining, Oil and Gas

Last Updated: March 20, 2023

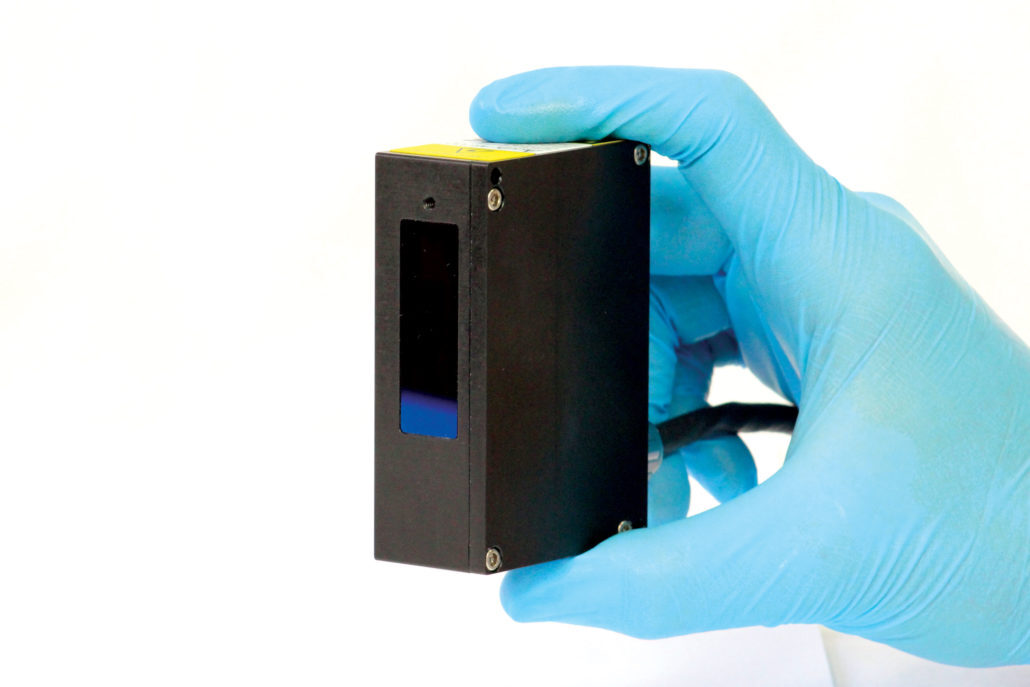

Laser Sensors Measure Drill Pipe Runout

Laser Displacement Sensors Are Used to Measure the Runout of Cylinders

Measuring the runout on cylinders is a simple task using laser displacement sensors. Align the laser path with the axis of rotation and collect your data at high speeds. Our laser displacement sensors have sampling rates up to 9.4Khz and linearity down to the micron to help ensure materials are within tolerance to meet the demands of manufacturers.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.