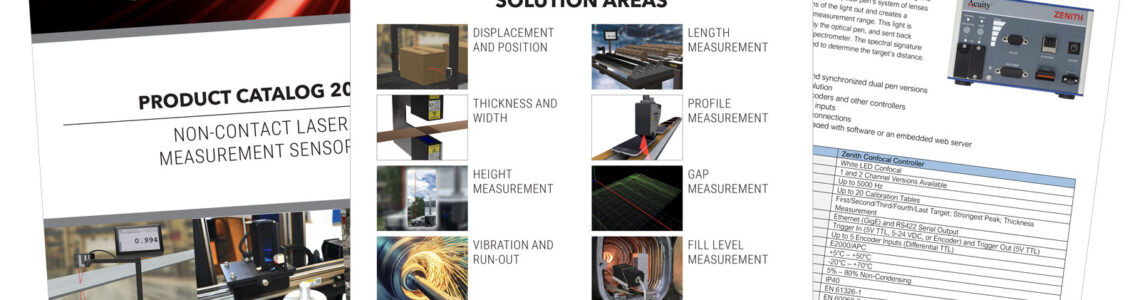

Inventory Management Systems by Measuring Thickness June 19, 2024 – Posted in: Thickness Measurement, Updates

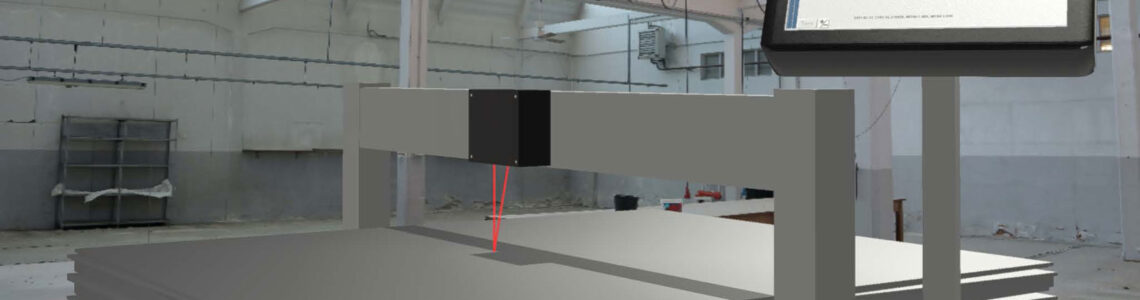

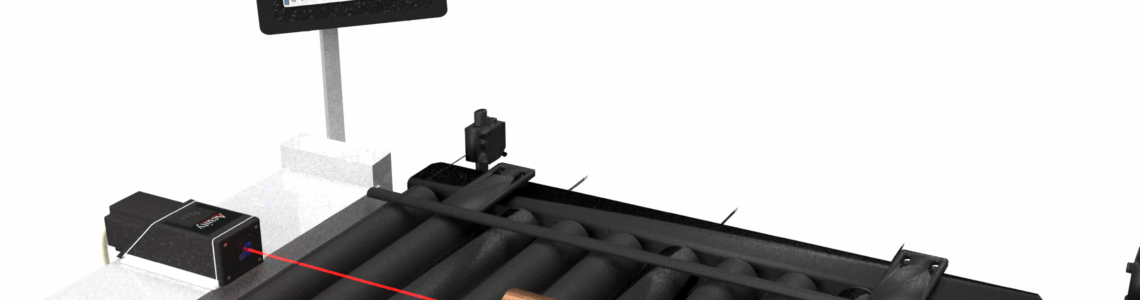

One method for monitoring inventory stacks and inventory management systems is using non-contact thickness measurement either during production, at an inspection station, or post-production.

Continue reading