Customization for Laser Measurement Sensors

At Acuity Laser, customization with measurement sensors is one of our core strengths

We use our expertise to solve challenging measurement applications, and we’ve worked with customers both large and small to provide customized laser sensors and solutions. Many of our products, such as the AR200 Laser Measurement Sensor and the AR700 Laser Displacement Sensor, have seen new versions develop out of real-world challenges our customers faced and that Acuity helped resolve.

We use our expertise to solve challenging measurement applications, and we’ve worked with customers both large and small to provide customized laser sensors and solutions. Many of our products, such as the AR200 Laser Measurement Sensor and the AR700 Laser Displacement Sensor, have seen new versions develop out of real-world challenges our customers faced and that Acuity helped resolve.

Measuring Deflection with Sub-Micron Accuracy

In one customized laser sensor example, an existing Acuity customer asked for a sensor to measure deflection with sub-micron accuracy in a tight contaminated space. To keep the laser out of the area that could damage the laser sensor, it needed to be highly accurate and use a single spot triangulation method.

In response we custom-created the AR700-2 long range model. This AR700 has the same small footprint as the AR700 compact unit (similar to the AR700-4). The sensor can measure with accuracy from 5″ out to 7″ from the face of the laser triangulation sensor. The 2″ measurement span provides a resolution of 0.0001″ with a linearity of better than +/- 0.0006″ over the full measurement span of 2″. The AR700-2L has all the same command and communications features as the existing AR700 product line.

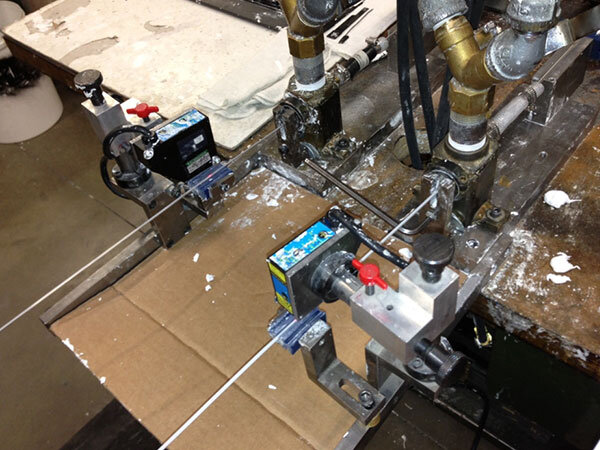

Measuring flux-core welding wire

In a different type of example, a manufacturer of flux-core welding wire needed to measure the height of the flux in a channeled wire. Crucially, the sensor needed to focus on the flux without landing on the walls of the metal wire. As well the customer needed to see the real-time measurement output as a graph on a large display for its employees to monitor.

After working with us, the customer chose the AR200-6 model due to its high accuracy and very small spot size. The AR200-6 is Acuity’s shortest range AR200 Laser Measurement Sensor that boasts a linearity down to 12µm and resolution less than 2µm. The AR200-6 model has a spot size as small as 35μm in diameter at the middle of its range. This provides insurance that the laser beam is focused strictly on the flux material for optimized height measurement.

For this flux-core welding wire project, Acuity custom-created a version of our user interface software to take multiple readings and display the readings as a graph on a large display. Adapting our touch panel display to display unique measurement data is a common type of customization for our team. Our 7-inch Acuity Touch Panel Display can control Acuity measurement sensors and display their distance readings. Using serial communications, the smart terminal includes software for calculating thickness and other dimensions without the need for a computer or software programming.

Measuring Battery Expansion

In a recent project that utilized our touch panel display, a manufacturer was looking to find a system to precisely measure the displacement of a battery cell during battery expansion measurement tests. The customer was looking to measure the battery cell expansion under cycling and other pressures in a controlled temperature environment.

In a recent project that utilized our touch panel display, a manufacturer was looking to find a system to precisely measure the displacement of a battery cell during battery expansion measurement tests. The customer was looking to measure the battery cell expansion under cycling and other pressures in a controlled temperature environment.

Using non-contact measurement, the customer was looking to analyze the locations of any battery expansion to see if it was uniform or not, all while maintaining accuracy down to a micron. As well the customer wanted an out-of-the-box solution without the need for software programming on their end.

After a few meetings, Acuity engineers suggested a setup of three AR700-0125 laser models and our Touch Panel Display. Custom software was written in order to calculate, display and record the individual displacement of the three lasers, as well as the x-slope, y-slope and center-z of the target surface. At a glance the customer can see the measurements on the touch panel display as well as export the data to other platforms.

Armed with that data, the customer is ready to guide their design during their next series of iterations.