Rubber Conveyor Belt Thickness Posted in: Thickness Measurement – Tags: Tire and Rubber Manufacturing

Last Updated: March 20, 2023

A year or two ago, a process engineer approached the Acuity team looking for a solution to measure the thickness of their rubber product directly on the production line. The customer was looking to measure the thickness of the material in a few locations – a common ask for thickness measurements. The customer’s product was a rubber conveyor belt, and the company needed the thickness measurement to enhance their quality control system. They needed highly accurate sensors with a system to process the thickness data for visual display and data storage for further analysis. The customer needed to install the laser sensors up to 16 inches away from the target material and have a measurement range of at least 2 inches, all while still maintaining high accuracy.

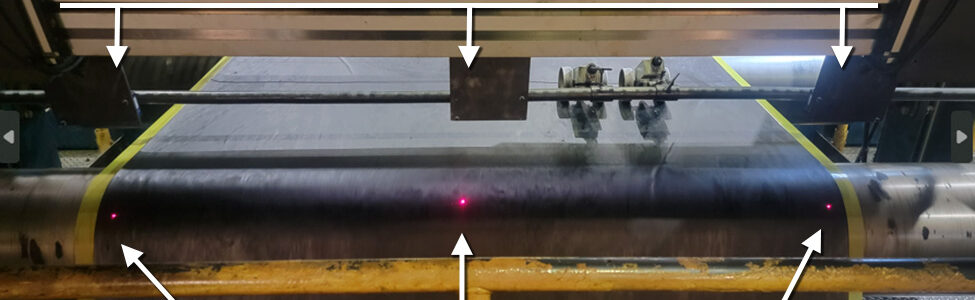

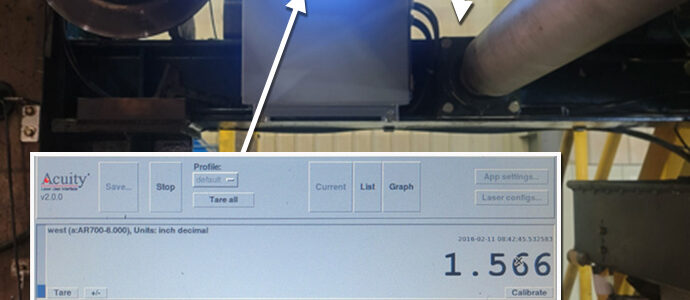

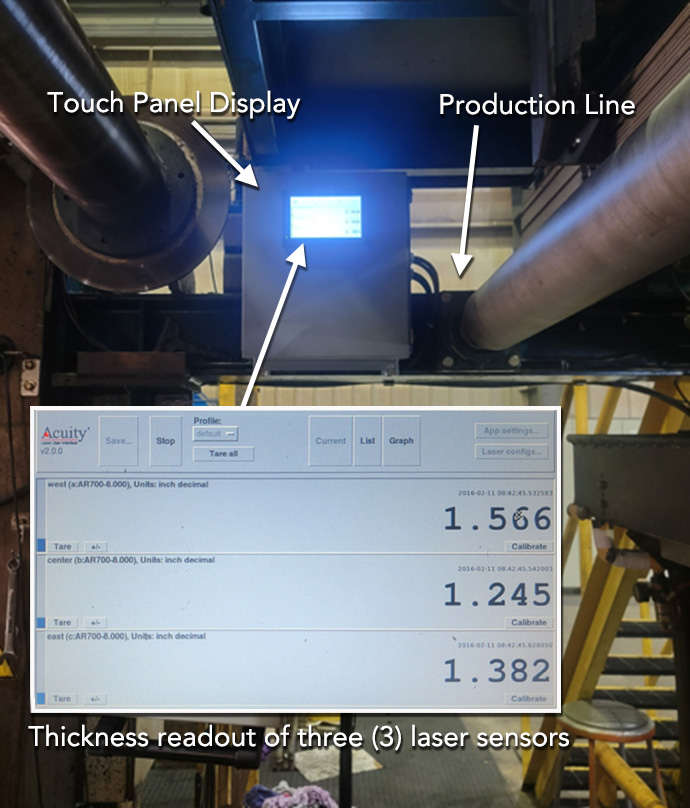

After back and forth with the process engineer, the Acuity team selected the following: (3) AR700-8 sensors and (1) Acuity touch panel display (TPD) for data analysis. The system selected was a single thickness measurement system. Instead of the more typical dual sensor thickness set up, the customer wanted to take the measurements of the material as it passes over the cylinder. With the TPD built-in software, this was an easy, out-of-the-box solution. As seen in the adjacent photos, once the sensors are set up on the metallic cylinder, all the customer has to do is use the built-in software to press “tare all”. This essentially “zeroes” all three sensors on the reference material, in this case, the metal cylinder. As the rubber material rolls over the cylinder, the TPD displays the difference in height measurement, which is the thickness of the material. Also seen in the photos, the customer decided on the placement of the sensors in three locations – on the left, middle, and right of the measurement material. This is a common practice for many thickness measurement applications because it allows the customer to not only gauge the thickness of the material but also to help gauge the thickness of the material across the width.

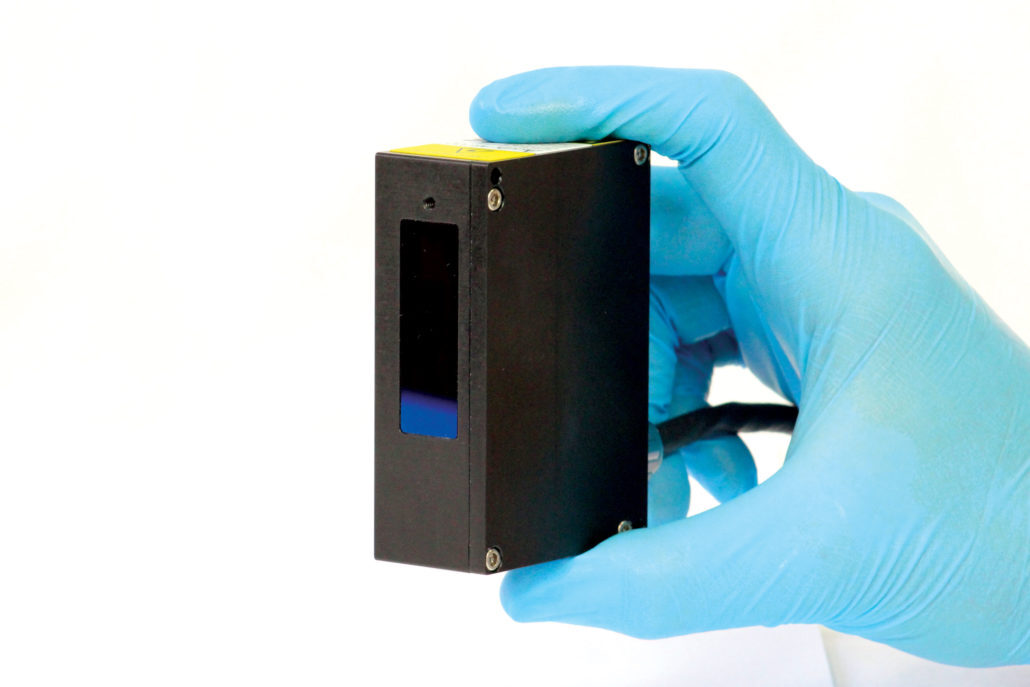

The AR700-8 Laser Displacement Sensors were selected for this measurement due to the range needed and high accuracy of the sensors. The AR700-8 model measures out to 16 inches, with 8 inches of measurement range. At an impressive accuracy of 0.03% of the span at that range, the AR700 was able to meet the precise measurement specs for this application, despite the sensor being installed far away from the target material. The other big reason the AR700 was selected for this application was due to its history of success on measurements of black materials over the years. During the sales process, the customer wanted to test the AR700 sensor to another competitor’s sensor to the comparison of measurements off the black material. At times, black material can be a challenge for lasers to get good, consistent readings. During demo testing, the AR700 sensor significantly outperformed the other sensor on the black material and was therefore selected for this application.

We recently checked in with the customer and they reported success. The system was expertly installed and performing as expected. We also learned that the customer has seen many benefits from the Acuity thickness system and are planning on retrofitting the system in multiple locations over the coming year.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.