Propeller Blade Profiling Posted in: AR700 Laser Displacement Sensor – Tags: Profiling Measurement

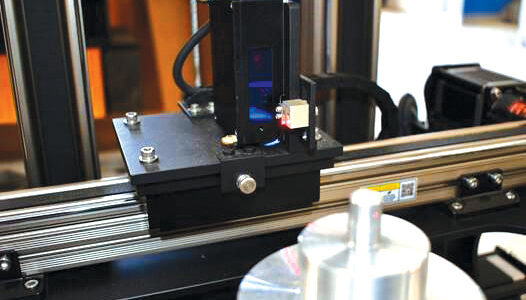

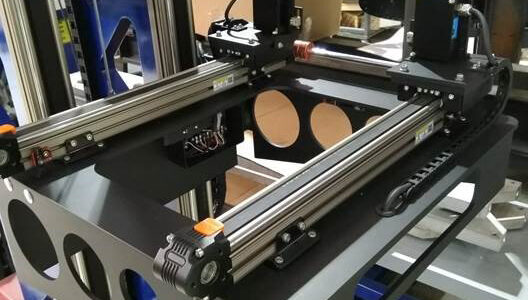

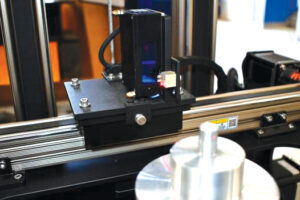

A major North American propeller manufacturer and service company selected a long-range triangulation sensor to measure the profile of its propellers and controllable tip blades during the manufacturing process. Non-contact measuring, like that afforded by laser sensors, is desirable in propeller manufacturing because the fixed measuring device can be installed with a large standoff away from bulky and/or moving parts.

A major North American propeller manufacturer and service company selected a long-range triangulation sensor to measure the profile of its propellers and controllable tip blades during the manufacturing process. Non-contact measuring, like that afforded by laser sensors, is desirable in propeller manufacturing because the fixed measuring device can be installed with a large standoff away from bulky and/or moving parts.

In this case, the customer chose a laser position sensor that had the best resolution while allowing them to measure the greatest pitch of the largest propellers and blades (difference in height between the leading and trailing edge).

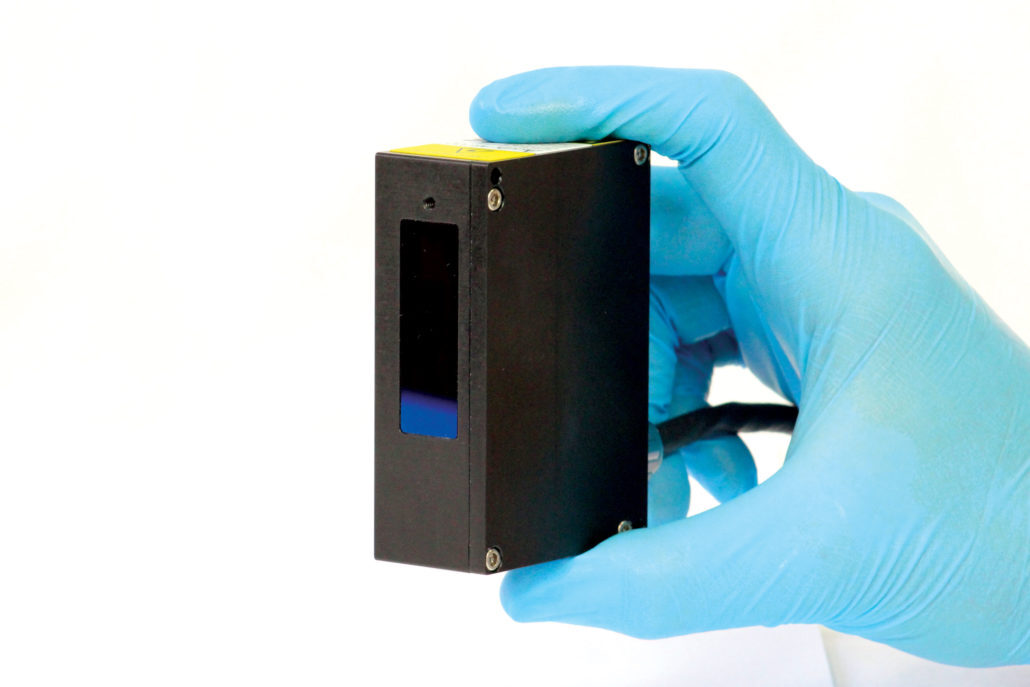

The typical surface finish of the propellers was a shiny, ground appearance, and was no problem for the Acuity AR700 laser displacement sensor with its highly-sensitive, digital CMOS detector array technology.

The typical surface finish of the propellers was a shiny, ground appearance, and was no problem for the Acuity AR700 laser displacement sensor with its highly-sensitive, digital CMOS detector array technology.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.