Lumber Thickness and Dimensions Posted in: Thickness Measurement – Tags: AR100, Automation, Building Materials and Equipment, Lumber Timber and Wood Products

Using Our Experience to Set Up Lumber Thickness Measurement Systems

Lumber Measurement Using a Laser Displacement Sensor

The forest, lumber and wood products industry is a regular user of Acuity laser sensor products for the measuring of logs, cants, lumber, veneer thickness, paperboard, etc.

The forest, lumber and wood products industry is a regular user of Acuity laser sensor products for the measuring of logs, cants, lumber, veneer thickness, paperboard, etc.

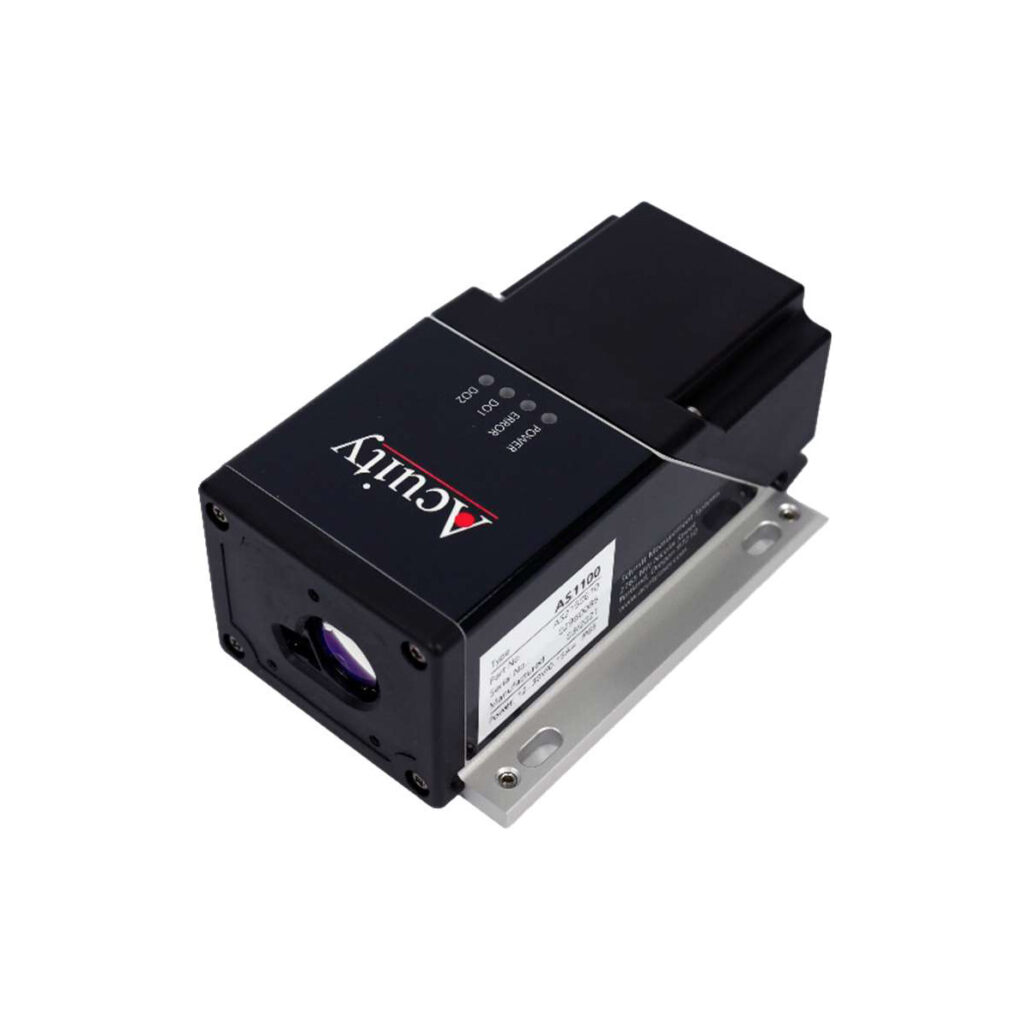

AR700 laser displacement sensors are commonly integrated into automated lumber finishing machines to measure board position, board dimensions and surface profiles. The long-distance AR100 laser triangulation sensor offers a valuable stand-off distance, keeping the measuring equipment away from the quickly moving lumber and potential hazards.

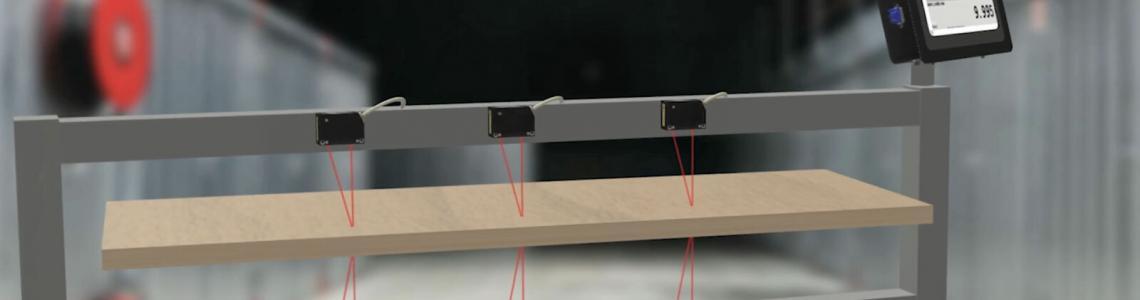

The below video at a customer’s site takes us through a common dual laser thickness measurement application in the lumber industry. As you can see in the video, the customer is using (4) pairs of dual opposing sensors (top and bottom placement) to measure thickness at (4) different locations of each board. Aligning one laser on top and one laser on the bottom is the most used technique to accommodate for the up and down vibration of the boards as it moves along the drag chain conveyor belt. This customer is then taking the lasers output data to calculate the thickness in their own data processing system. Similar to many other thickness applications, the customer’s data processing system is using the thickness data to control the rest of their machine and at the end of this conveyor line, you can see the boards are being separated into different sorting lines based on their thickness.

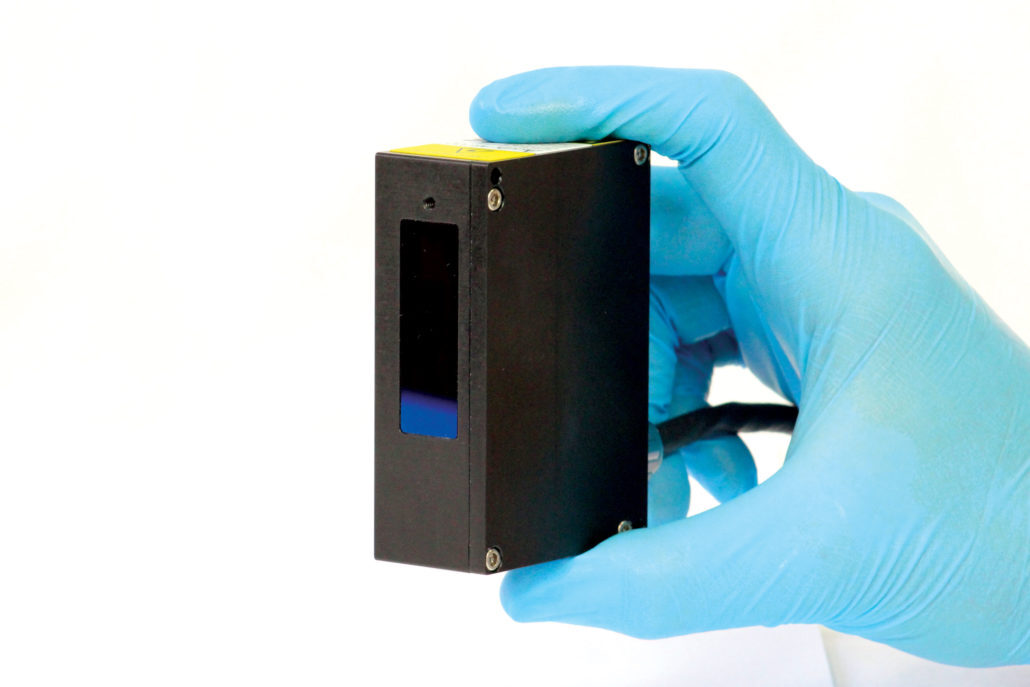

Acuity has been selling lasers into the lumber/forestry industries for thickness measurement applications for over 20 years. Different lumber product types including plywood thickness, veneer thickness, paperboard thickness, and more have been successfully measured with our lasers during that time. The environment of lumber industries such as sawmills and plywood manufacturing plants present special challenges due to their dusty environments. Getting saw dust or any other form of debris onto sensors can throw off measurements significantly or stop measurements completely. To avoid this, we always advise customers to keep the laser sensors clean by using forced air flow in front of the sensors window. Air nozzles blow pressurized air across the optical windows to prevent buildup of dust and debris that could diminish measurement accuracy. As you can see from the adjacent picture, despite the dirty environment, the air nozzles are able to keep the sensor’s windows clean to provide precise and reliable thickness measurements.

Acuity has been selling lasers into the lumber/forestry industries for thickness measurement applications for over 20 years. Different lumber product types including plywood thickness, veneer thickness, paperboard thickness, and more have been successfully measured with our lasers during that time. The environment of lumber industries such as sawmills and plywood manufacturing plants present special challenges due to their dusty environments. Getting saw dust or any other form of debris onto sensors can throw off measurements significantly or stop measurements completely. To avoid this, we always advise customers to keep the laser sensors clean by using forced air flow in front of the sensors window. Air nozzles blow pressurized air across the optical windows to prevent buildup of dust and debris that could diminish measurement accuracy. As you can see from the adjacent picture, despite the dirty environment, the air nozzles are able to keep the sensor’s windows clean to provide precise and reliable thickness measurements.

Lumber can also present challenges to laser sensor manufacturers due to the infrequent dark-colored knots on the lumber while measuring. Despite these challenges, Acuity sensors have been able to perform well on all sorts of lumber. This is largely due to the sensor’s automatic gain control feature. This is a feature on some of our lasers such as the AR200 Laser Measurement Sensor and AR700 Laser Displacement Sensor that use internal sensor feedback to automatically adjust the laser power output based off target color/finish. This enables control for different color changes that may reduce the amount of light needed to be received by the sensor’s detector.

Here is a look at one of our lumber thickness setups from 15 years ago. As you can see from the picture, much like the video today, we had (4) sets of lasers to measure the location at (4) different locations. This was our AR600 model, which has now been replaced by our new highest end model, the AR700. The experience our team has gained over the years in lumber thickness applications enables us to work closely with customers in all stages of development. Successfully choosing the right laser sensor manufacturer for thickness applications is important. For most thickness applications, the laser is only a piece of the bigger picture. Advice and guidance on mounting and processing the sensor’s data are critical factors towards your decisions, and our experienced Acuity team is here to guide you. Please contact us today for any of your measurement questions.

Here is a look at one of our lumber thickness setups from 15 years ago. As you can see from the picture, much like the video today, we had (4) sets of lasers to measure the location at (4) different locations. This was our AR600 model, which has now been replaced by our new highest end model, the AR700. The experience our team has gained over the years in lumber thickness applications enables us to work closely with customers in all stages of development. Successfully choosing the right laser sensor manufacturer for thickness applications is important. For most thickness applications, the laser is only a piece of the bigger picture. Advice and guidance on mounting and processing the sensor’s data are critical factors towards your decisions, and our experienced Acuity team is here to guide you. Please contact us today for any of your measurement questions.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.