Principles of Operation:

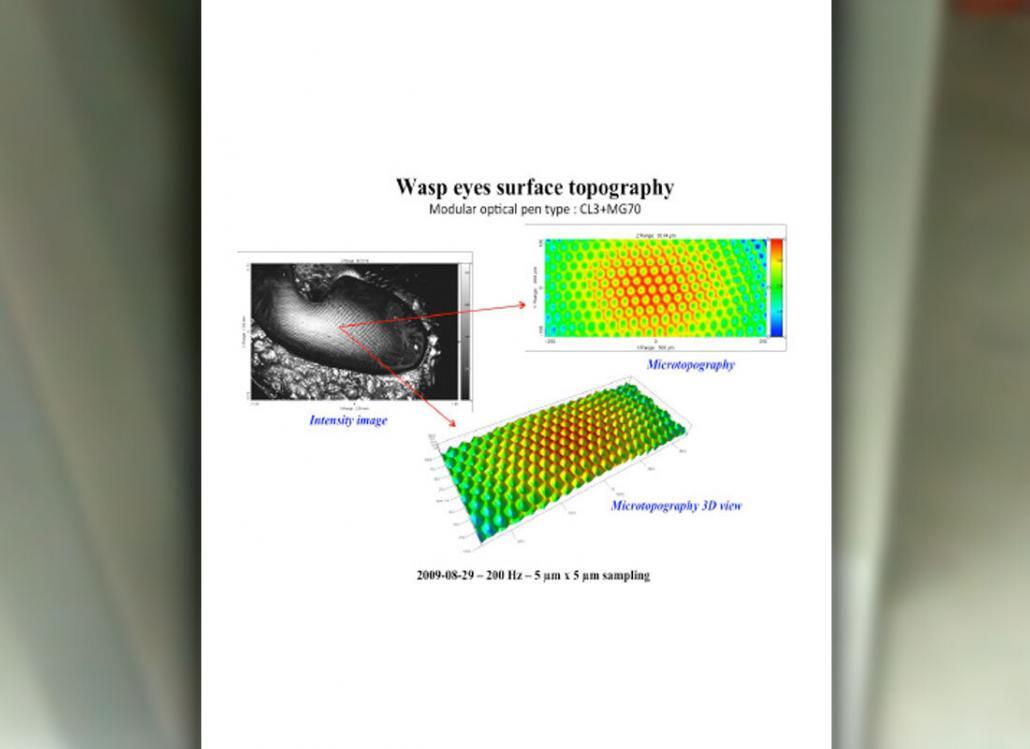

The Zenith controller transmits white light through a fiber optic cable that is focused on the target with a multi-lens optical pen. As the light is focused, the chromatic aberration of the optical pen’s system of lenses spreads the individual wavelengths of the light out and creates a spectrum of focal points over the measurement range. This light is reflected off the target, collected by the optical pen, and sent back through the fiber optic cable to a spectrometer. The spectral signature of the reflected light is then analyzed to determine the target’s distance.

Features:

- Available in single pen and synchronized dual pen versions

- 15-bit measurement resolution

- Can synchronize with encoders and other controllers

- Supports up to 5 encoder inputs

- GigE Ethernet an RS422 connections

- Configuration can be managed with software or an embedded web server