Plywood Sheet Thickness Gauging Posted in: Thickness Measurement – Tags: Lumber Timber and Wood Products

Non-Contact Laser Thickness Measurement of Plywood and Oriented Strand Board

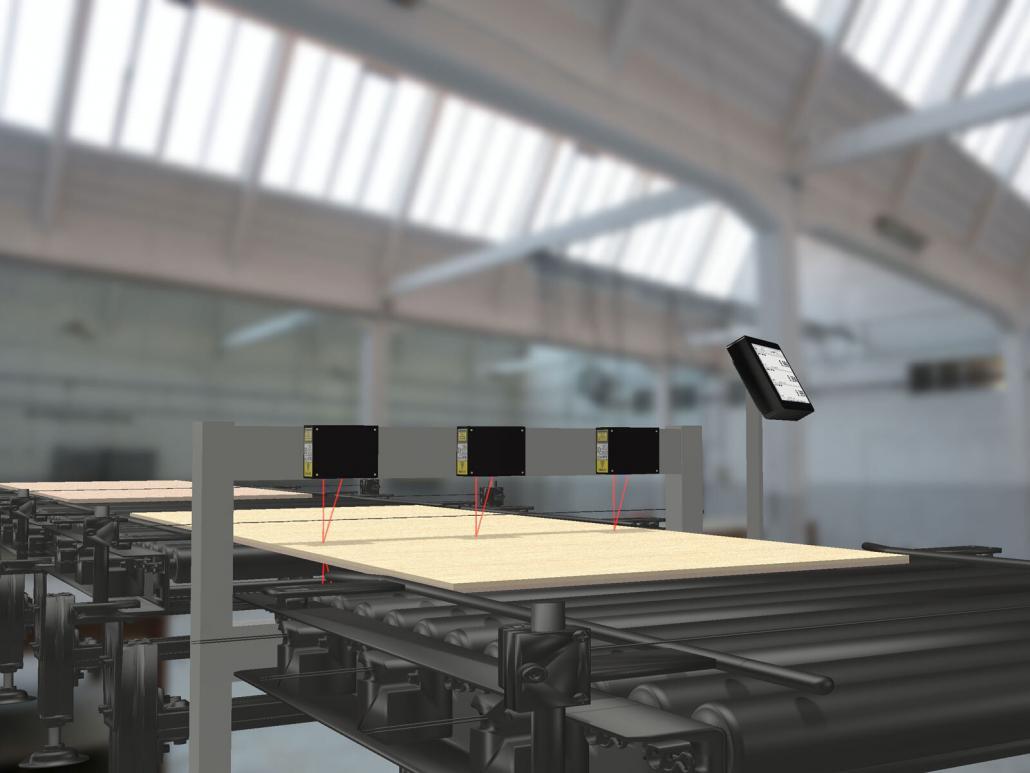

Sawmills are harsh environments that demand accurate laser sensors under dusty conditions. Production of plywood and OSB (oriented strand board) sheet is highly automated. Several Acuity customers are system integrators who develop specialized instruments for the forest products industry.

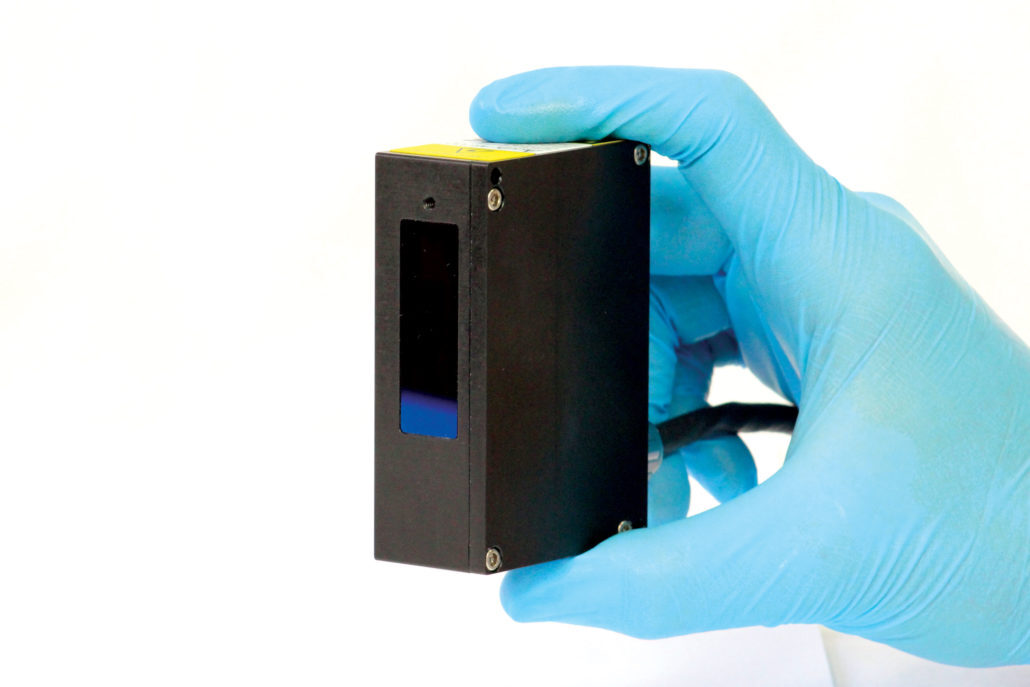

One machine builder chooses AR700 laser displacement sensors in opposing pairs to measure dimensions of wood sheets in several locations. The AR700 with a CMOS detector array performs well on plywood, despite the presence of dark-colored knots. Thickness gauging is important because thin boards are inferior and sheets that are too thick waste materials and resources.

Sawmills and plywood manufacturing plants present special challenges because they are dusty environments. All laser sensor equipment is kept clean using forced air. Air nozzles blow pressurized air across the optical windows to prevent buildup of dust that could diminish measurement accuracy.

Gallery of Plywood Sheet Thickness Gauging

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.