Calculating Coil Length in Rolls Posted in: Length Measurement – Tags: Automation, Metal and Steel Production

Last Updated: May 8, 2025

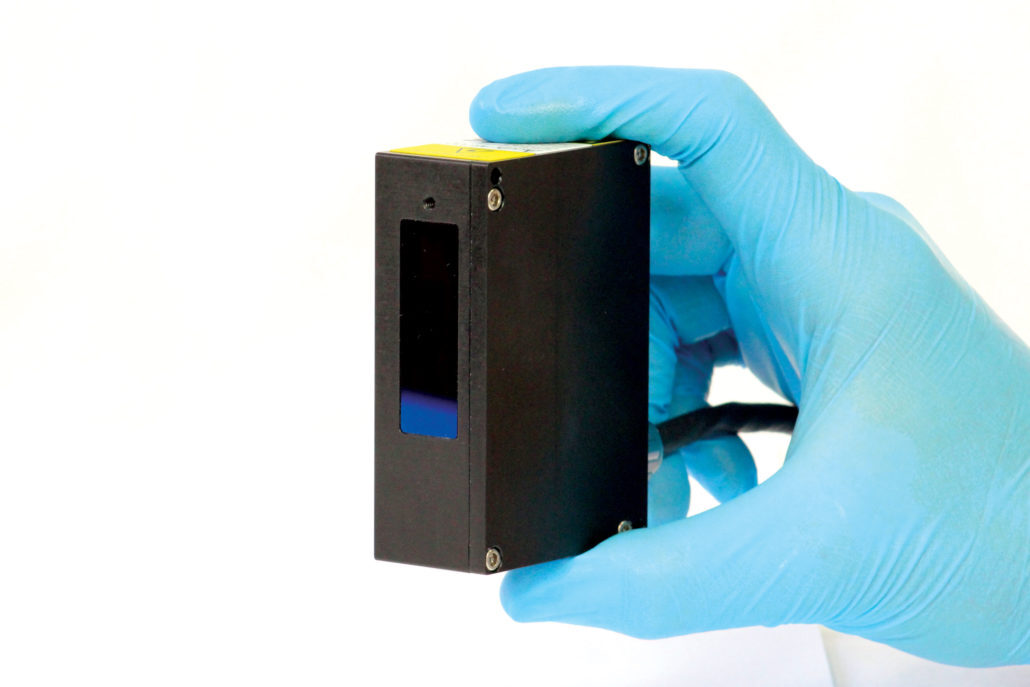

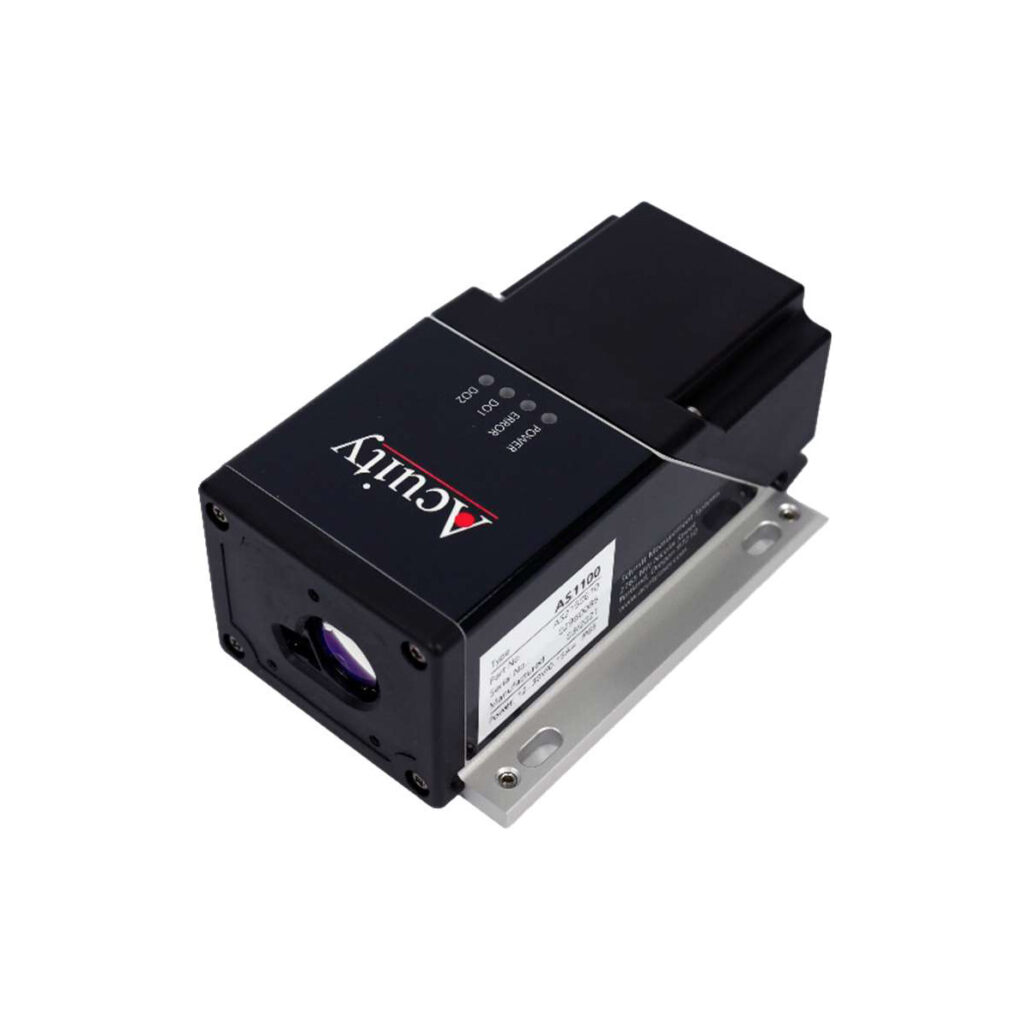

Acuity sensors are ideal for measuring coil roll length. Do you need to monitor your coil roll production? Need to estimate how much material is left on a roll? With careful setup and simple geometry, you can use our sensors to calculate coil length and get accurate non-contact coil length measurements.

Common materials for coil rolls include steel (carbon steel, stainless steel, galvanized steel), copper, aluminum, and various alloys. To get started, you’ll need to know some base dimensions, such as your material thickness and the inner radius of your roll.

How to Calculate Coil Length

Here we will give you a quick primer on how you can use an Acuity laser sensor to monitor your coil roll application.

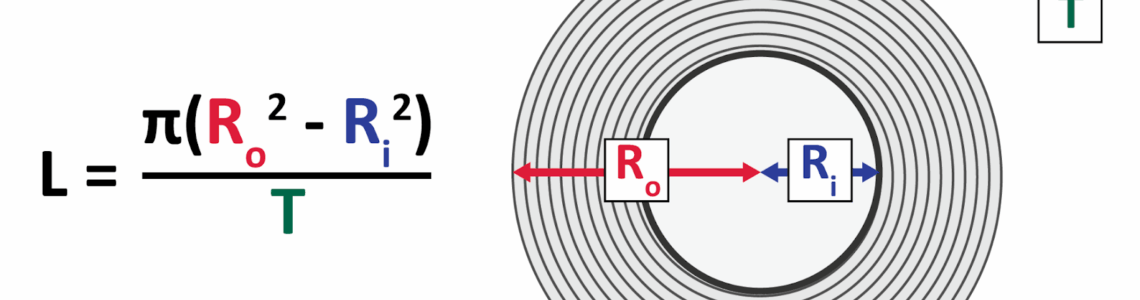

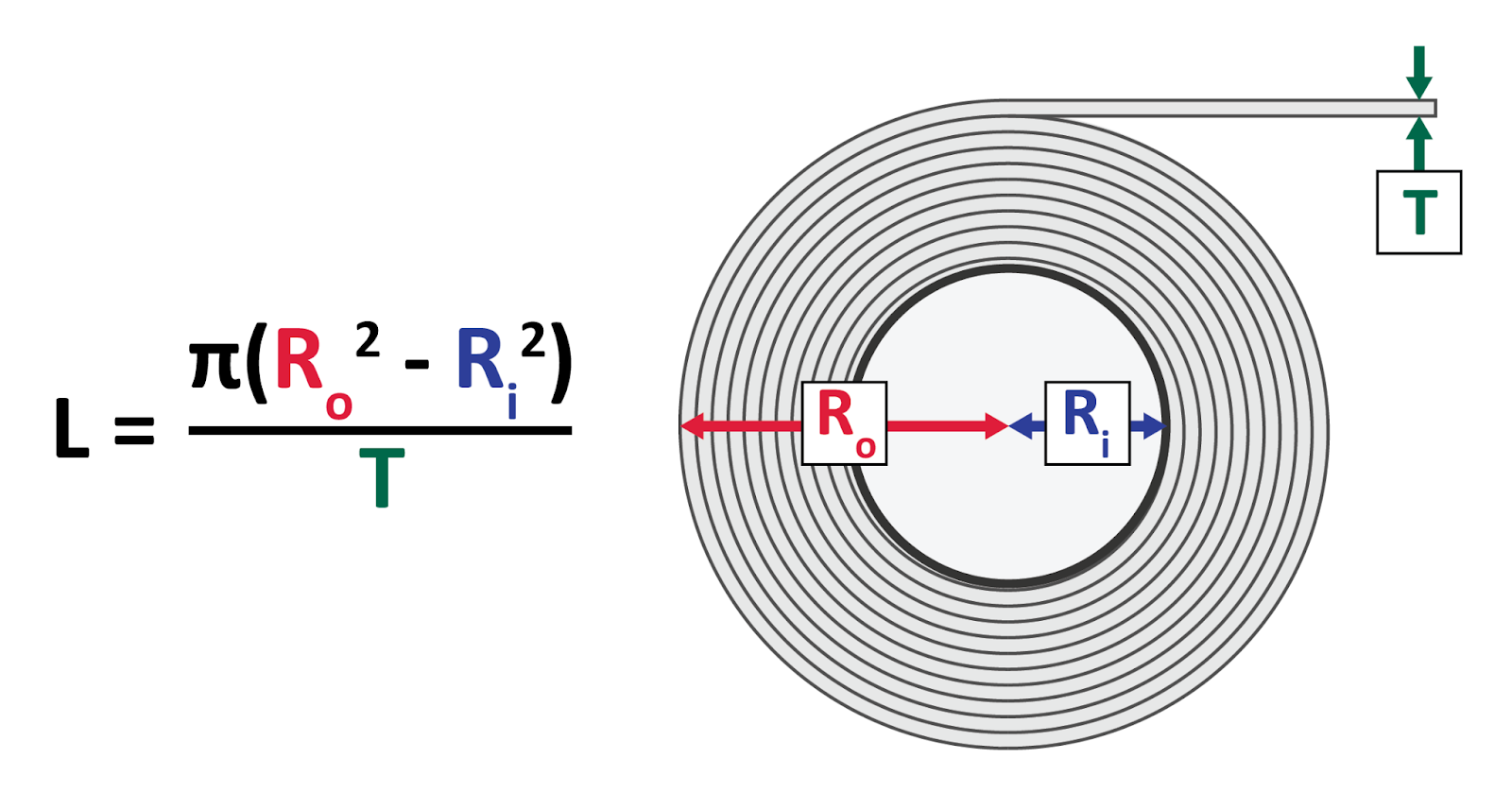

We need to start with a little math to make sure we’re all on the same page. Here is the equation for the length of material on a coil roll.

Where:

L – Length of the coil roll material

Ri – Inner radius of the coil

Ro – Outer radius of the coil

T – Thickness of the material

π – Pi (mmmm… pi)

The thickness of the material and the inner radius of the coil roll should be known. The outer radius will be measured by the sensor.

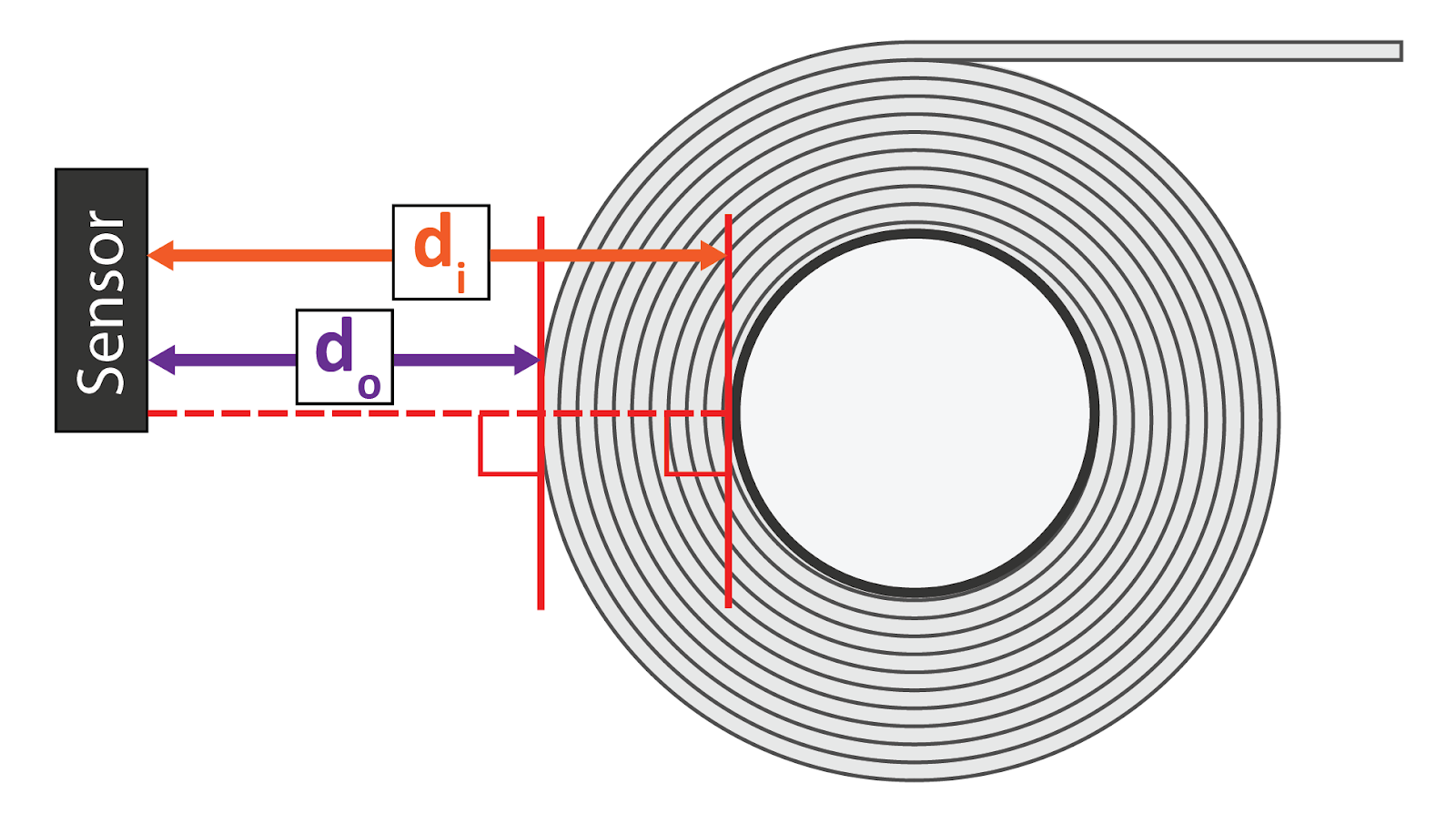

Speaking of measurement, the sensor should be set up like this:

The sensor should be set up so that the laser beam is pointed directly at the center of rotation. This will ensure the sensor is measuring perpendicular to the target surfaces. In the above diagram:

di – Sensor distance measurement of the inner surface (mount)

do – Sensor distance measurement of the outer surface

do is going to be the variable, measured by the sensor, that will change as the roll is wound or unwound.

If you are not able to measure to the mount or inner surface of the coil roll, you will need to take the thickness of the whole coil roll and add that to the initial do measurement to get di.

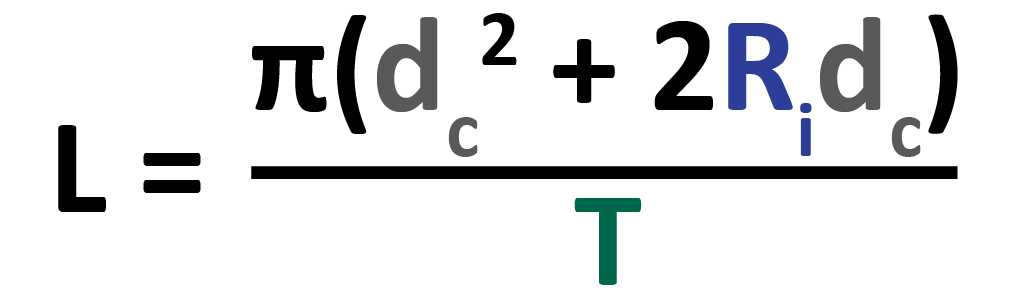

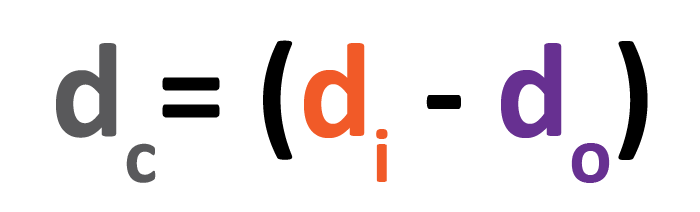

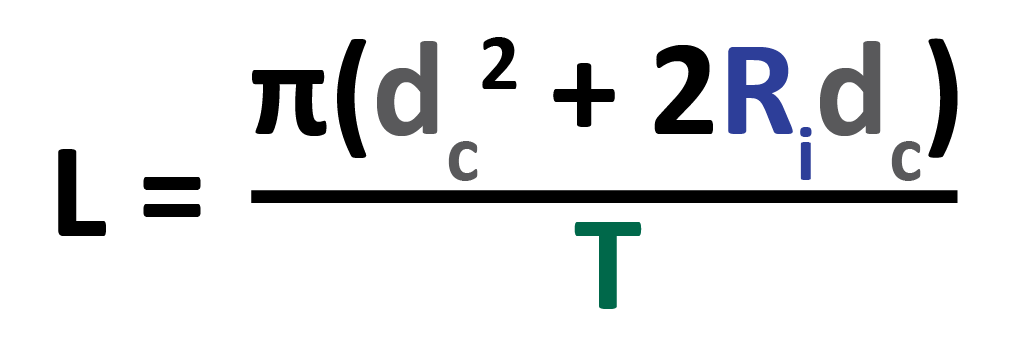

Now we clean up the math:

Get the current thickness of the entire coil roll (dc) by subtracting the measurement to the inner surface (di) by the current measurement of the outer surface (do). That may seem strange, but to the sensor, the inner surface is further away, so it will have a larger measurement, and we only really care about the difference between the outer and inner.

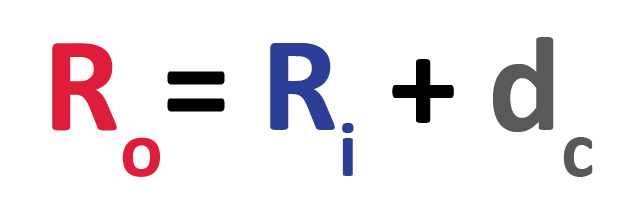

We can use that to calculate the current outer radius in the original equation by adding it to the inner radius (Ri).

Now substitute that into the original equation, do a little algebra, and you get the final equation:

And there you have it! One sensor can tell you how much material is on your coil roll in real time. Contact our sales team, and we can help you find a laser sensor that can work for you.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.