Aluminum Billet Scalping Posted in: Profiling Measurement – Tags: Metal and Steel Production

Last Updated: March 20, 2023

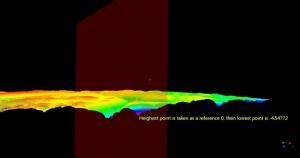

Laser Sensors Profile Billet to Help Ensure Aluminum Billets Are Square

Acuity’s AP820 is used to profile aluminum and steel billets with high repeatability and speed before scalping. Several Acuity AP820 2D laser scanners can be mounted in parallel to cover the whole width of the ingot with one scan. The lasers produce a 3D point cloud of the raw ingot surface giving way for software to accurately calculate the coordinates of the highest and deepest levels of the surface.

Our laser scanners replace the need to manually measure the deepest point of the ingot surface and adjust the scalping height of the machine accordingly. Manual measurement usually results in cutting too much material or leaving a surface with defects, resulting in wasted time.

Our laser scanners replace the need to manually measure the deepest point of the ingot surface and adjust the scalping height of the machine accordingly. Manual measurement usually results in cutting too much material or leaving a surface with defects, resulting in wasted time.

Acuity offers different models of AP820 line scanners that have an X measuring range (field of view) up to 650mm and a Z measuring range (height) up to 1000mm. The resolution in the X axis is 580 pixels, providing precise measurements. Contact Acuity for more information.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.