Steel Plate Width and Edge Control Posted in: AccuProfile 820 Laser Scanner – Tags: AP820, Metal and Steel Production, Position Measurement, Width Measurement

Last Updated: March 29, 2023

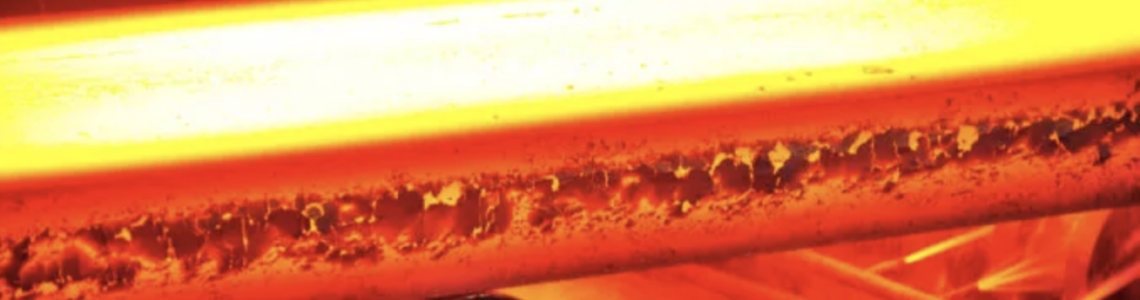

One of Acuity’s customers is a large sheet metal fabricator and is using one of our AP820 blue laser line sensors to control the position of the steel plate in the slitter line. By generating a laser line that is over 30″ long the customer can determine the edge of both sides of the steel plate and perform edge control measurement relative to the position of the center line for slitting the plate.

By also knowing both edge positions, the width of the steel plate can be calculated very accurately and with 100 laser line profiles a second. The long range AP820 has a large 2d laser sensor measurement span and uses a blue laser line so we can also measure on hot metals very accurately where red lasers have difficulty.

Since the AP820 is providing a profile using 580 points across the target we can also measure the height of thickness of the steel sheet which can be used to verify the steel plate is not too thin or thick for future rolling applications.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.