Thickness Measurement

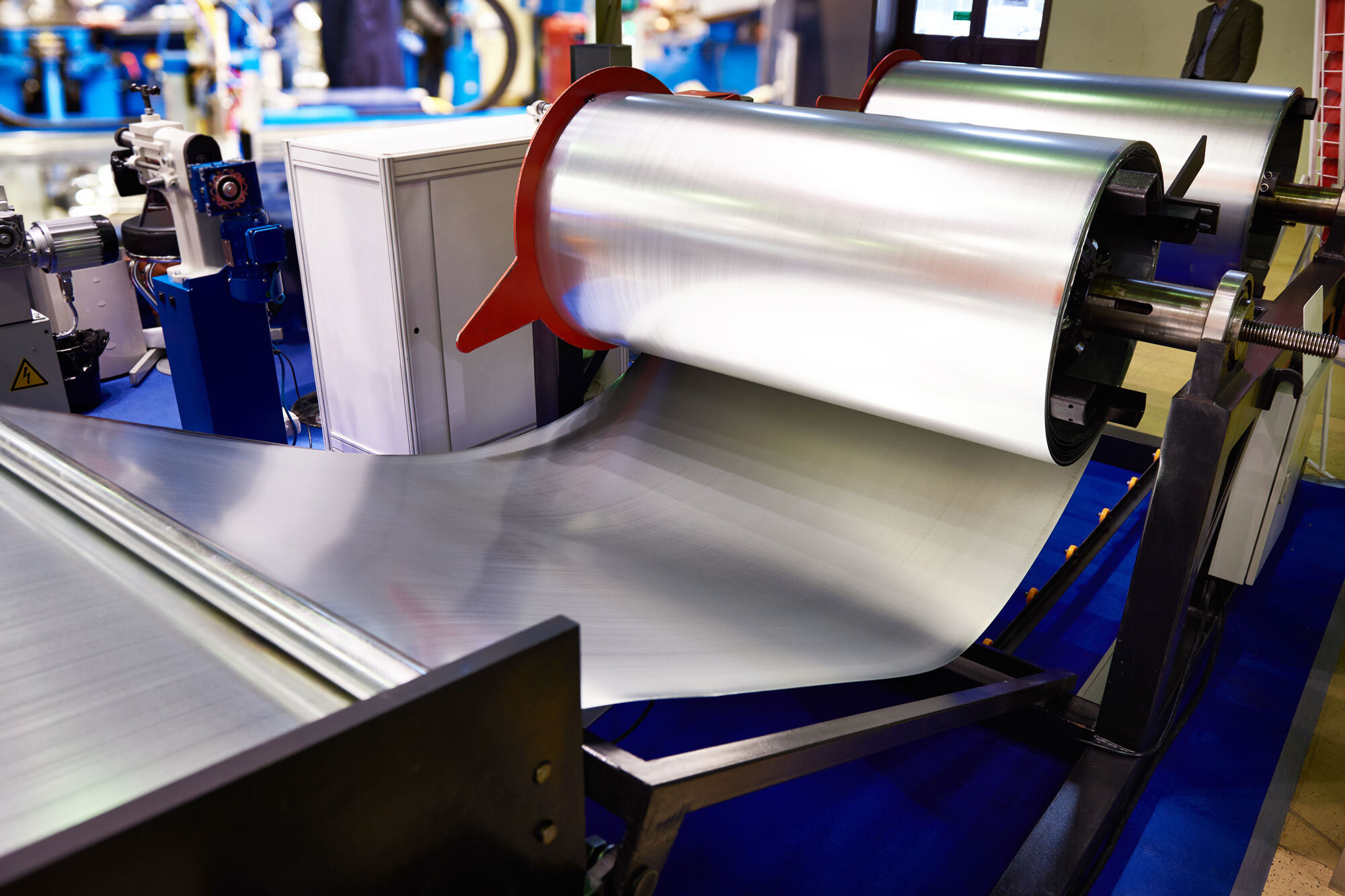

Laser Measurement Sensors Measure Thickness Of Materials

Thickness Is The Simplest Measurement Done With Laser Sensors

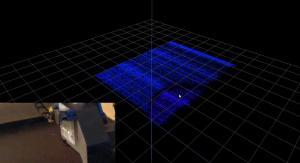

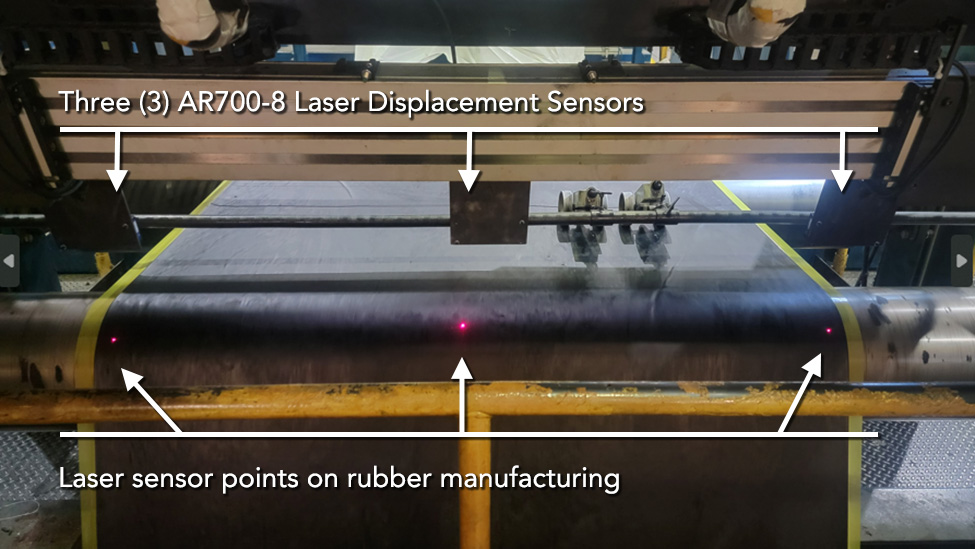

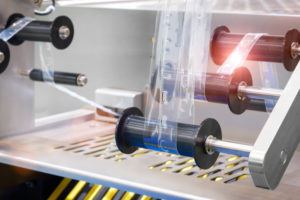

When deciding the best way to measure thickness, it is important to consider factors such as the material target and type of measurement (range, accuracy, speed). It is also important to distinguish between one-sided and two-sided measurement. If a material rests against a reference surface like a conveyor or table, one sensor is used to measure material thickness. Otherwise, dual opposing lasers measure materials that pass between for inline measurement.

When deciding the best way to measure thickness, it is important to consider factors such as the material target and type of measurement (range, accuracy, speed). It is also important to distinguish between one-sided and two-sided measurement. If a material rests against a reference surface like a conveyor or table, one sensor is used to measure material thickness. Otherwise, dual opposing lasers measure materials that pass between for inline measurement.

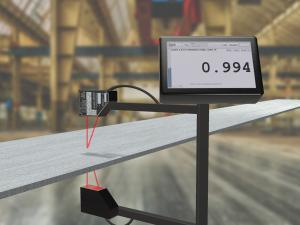

Due to the synchronization of our dual thickness lasers, non-contact measurement occurs at the same time and is therefore immune to the vibration of the material, resulting in precise readings. Our thickness laser devices are used to enable the customer to run at the low end of their tolerance range without crossing any limit thresholds. In turn, this increases productivity, improves quality control, and saves time and money on material management.

Advantages of non-contact measurement with displacement sensors include their non-destructive technique, ability for single-sided continuous thickness measurement, ability to cope with coatings, linings, etc., and high accuracy (0.1 mm and less) using standard timing techniques.

As well it can be easily deployed, does not require laboratory conditions, and requires relatively affordable equipment. Material and shape types include sheets, foils, insulation, layers, boards, rubber, plates, aluminum, clear film, polymers, rolled steel, plywood, plexiglass, polyethylene and more.