Electronics Manufacturing

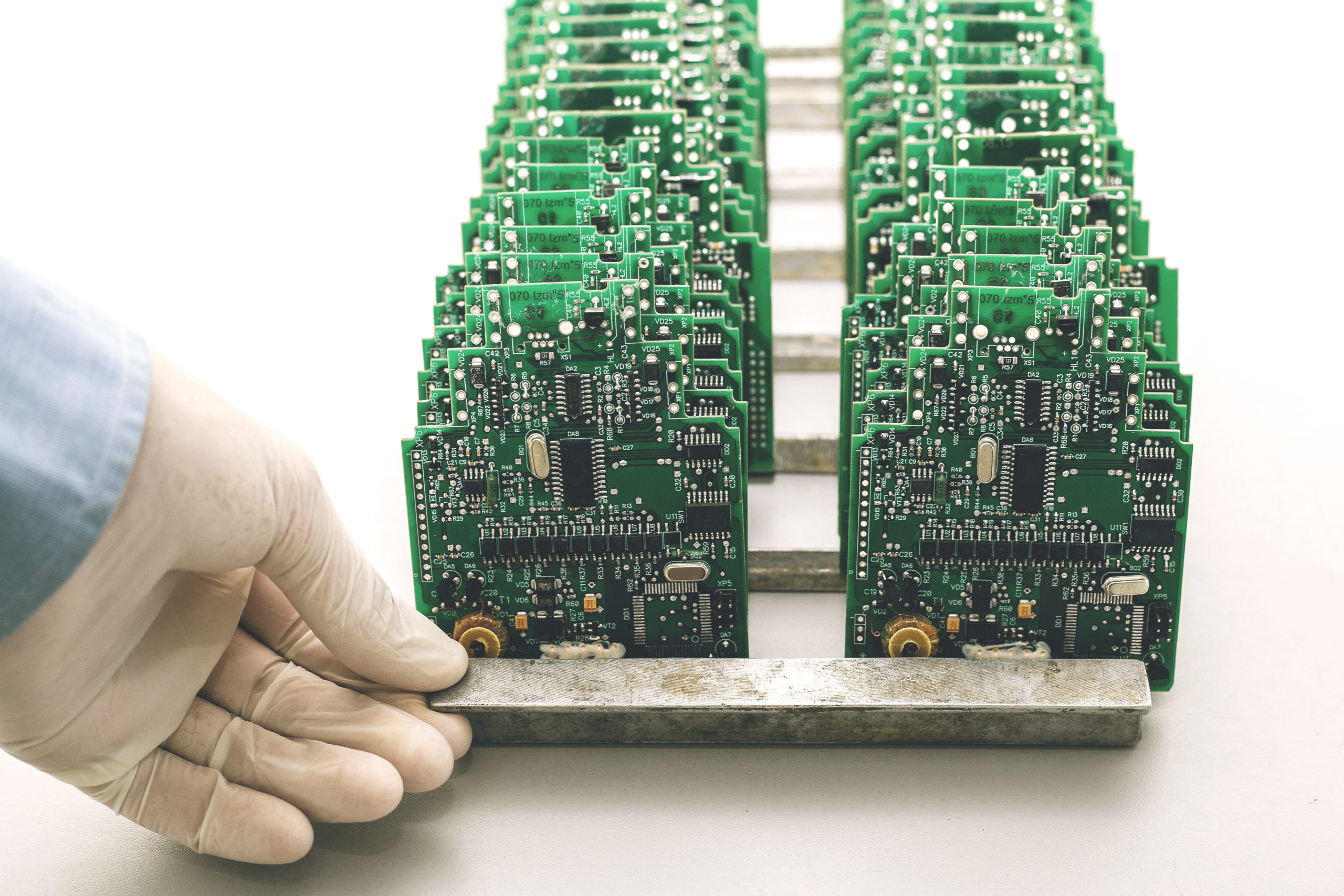

Laser Sensors for the Electronics Manufacturing and Defense Contractor Industries

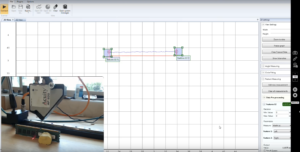

Today’s electronics are miniaturized, demanding ever tighter dimensional tolerances so that the components can fit inside ever smaller form factors. The slightest variation in component size or shape could result in improper mating of adjacent items or an inability to maintain a seal, thus jeopardizing the sustainability of the device. Acuity’s most accurate laser sensors, 2D line scanners and confocal devices measure dimensional tolerances of these components during manufacturing and quality assurance. Some examples of sensors in electronics manufacturing include a laser sensor used to measure the displacement of a diaphragm on a pressure transducer, a confocal sensor on a precision XY stage used to inspect features on a circuit board, and a laser sensor used to measure the profile of a housing for hearing aid assembly.

This application list is not intended to be exhaustive. The measuring tasks are by no means limited to these examples, and may serve as a suggestion for similar or completely different applications.