Pavement Measurement with Laser Sensors Posted in: Profiling Measurement – Tags: Transportation

Profilometers provide high-quality pavement measurement of deformations at highway speeds. The equipment measures the longitudinal and transverse road profiles, International Roughness Index (IRI), wheel path rut depth, Ride Number (RN) and macro texture of asphalt and concrete surfaces.

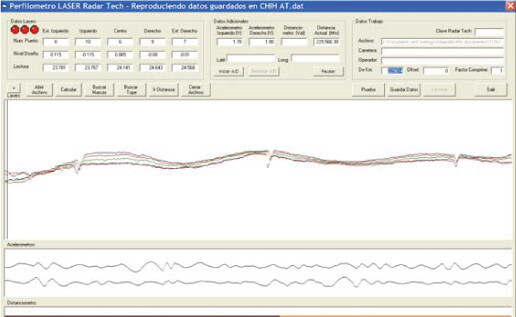

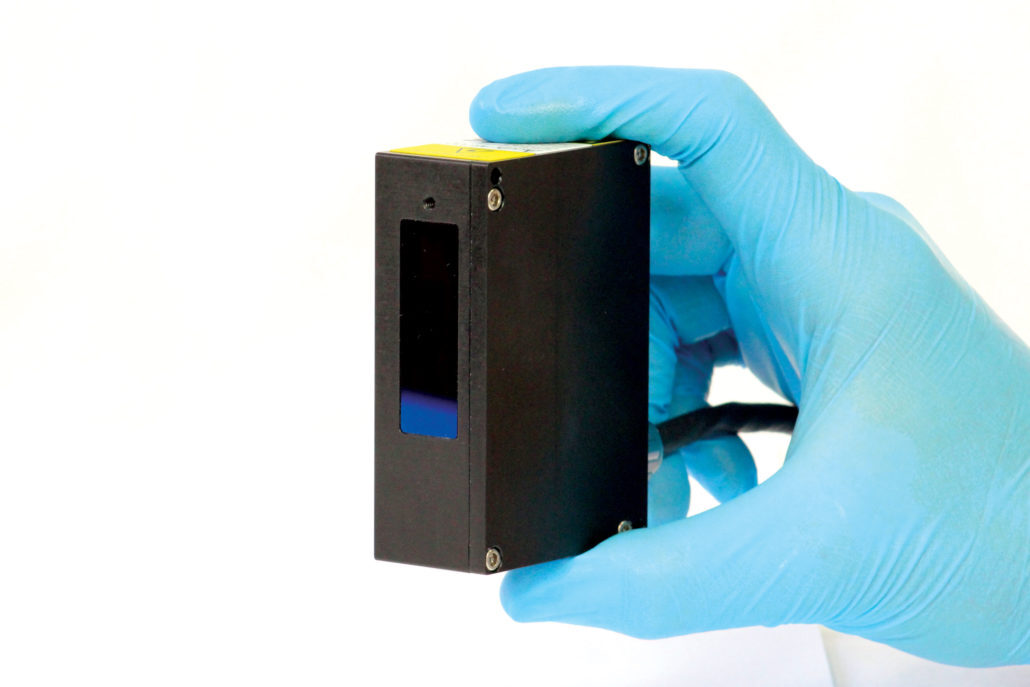

Road profilers use multiple laser sensors to measure longitudinal and transverse road profiles at highway speeds. Road profiling equipment can be installed on a variety of vehicles. The system has five or more laser displacement sensors installed in the front of the vehicle. Each laser sensor measures the height between the vehicle body and the pavement surface at rates up to 3,500 measurements per second with a precision superior to 0.06mm.

Measurements are made at the current transit speeds on city and highway roads ranging from 25km/hr to 140 km/hr. Two encoder sensors provide pavement measurements of the distances traveled by the vehicle, two accelerometers measure the vertical body bounce that the vehicle and the lasers experience when going over the pavement deformations, and a GPS device collects the geographic coordinates of the route traveled by the vehicle.

The computer inside the vehicle simultaneously collects the measurements of all lasers, distance linear chainage, accelerometers and georeference. Each laser measurement is influenced by the instant vertical movement of each sensor when driving over the pavement. Because of this, the accelerometers measure this movement and the computer program removes its influence when generating reports with the longitudinal and transversal profile of the pavement. Each laser meter obtains a longitudinal pavement profile composed by more than 40,000 measures on each kilometer, approximately one measurement for every 2.54cm of travel! With the simultaneous measurement of the 5 or more lasers, a transvere profile is obtained, which is used to calculate the rut depth for both wheel paths. This value reflects the structural weakness of the pavement produced by the transit load.

The computer inside the vehicle simultaneously collects the measurements of all lasers, distance linear chainage, accelerometers and georeference. Each laser measurement is influenced by the instant vertical movement of each sensor when driving over the pavement. Because of this, the accelerometers measure this movement and the computer program removes its influence when generating reports with the longitudinal and transversal profile of the pavement. Each laser meter obtains a longitudinal pavement profile composed by more than 40,000 measures on each kilometer, approximately one measurement for every 2.54cm of travel! With the simultaneous measurement of the 5 or more lasers, a transvere profile is obtained, which is used to calculate the rut depth for both wheel paths. This value reflects the structural weakness of the pavement produced by the transit load.

The international standard ASTM E950-98 dictates this type of measurement and classifies these types of Road Profilers within Class 1, which corresponds to the greatest precision. The IRI is calculated in accordance to World Bank requirements.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.