Molten Aluminum Level Posted in: Fill Level Measurement – Tags: Metal and Steel Production

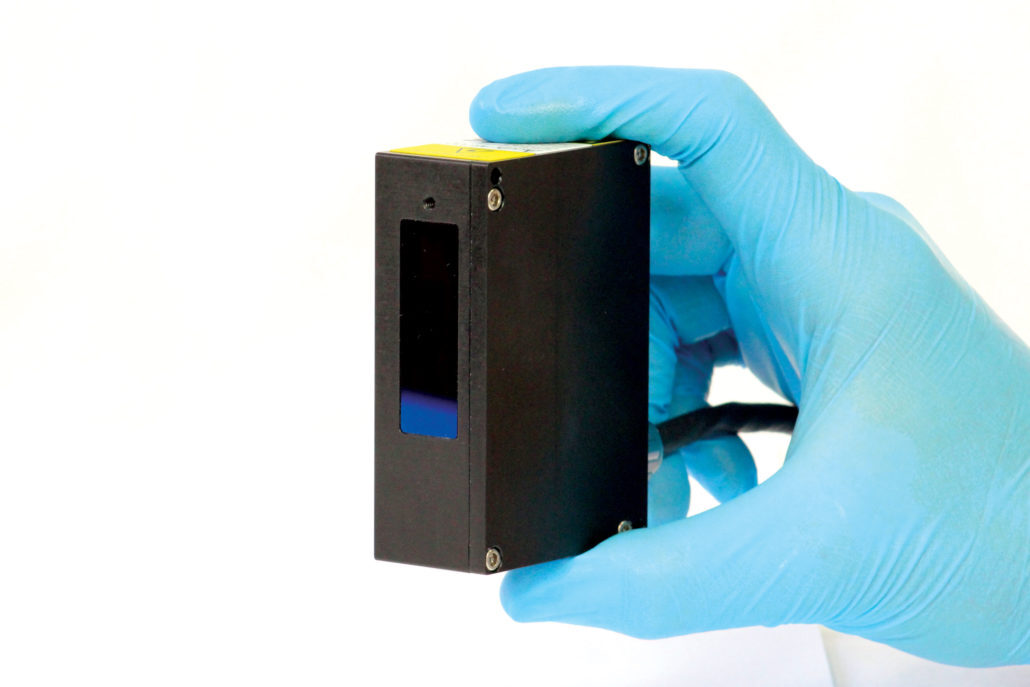

During the casting process, the AR700 laser displacement sensor is used to measure molten levels by monitoring the surface location of the aluminum mold. In order to obtain a homogeneous oxide-free cast, the height of the mold must be precisely monitored to keep an eye on fill level measurements.

AR700 sensors are used to precisely measure the fill height of the pour and communicate with the customer’s PLC to monitor and automatically shut down the pour. Keeping the sensor in protective cooling enclosures keeps the sensor protected from the heat rising from the molten aluminum.

Related Products

Sarah has been our technical support and sales engineer for 5+ years. If you've ever reached out to Acuity Laser for tech support, more than likely, Sarah is the one who helped you.